10 Ton Pipe Welding Rollers Self Aligning 2800 Mm For Wind Tower

✧ Introduction

1.The vessel diameter range lies within 320-2800 mm .

2.One set powered / One set idler / Electric control system.

3.Customers can customize 10 ton self - aligning welding rotators to their specifications.

4.10 ton Self - aligning welding rotator can controlled by handbox and foot pedal.

5.Rubber wheel or steel wheel following your repuire

6.Self - aligning welding rotator is easy to operate.

✧ Main Specification

| Model | SAR -10 Welding Roller |

| Turning Capacity | 10 ton maximum |

| Loading Capacity-Drive | 5 ton maximum |

| Loading Capacity-Idler | 5 ton maximum |

| Vessel size | 320~2800mm |

| Adjust Way | Self aligning roller |

| Motor Rotation Power | 1.1 KW |

| Rotation Speed | 100-1000mm/min Digital display |

| Roller size | Ø300*150mm |

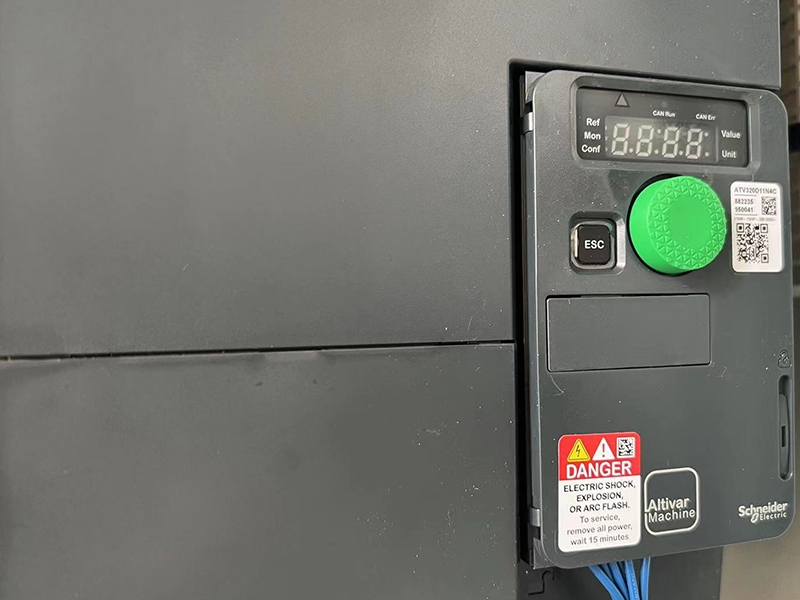

| Speed control | Variable frequency driver |

| Roller wheels | Steel coated with PU type |

| Control system | Foot pedal 8m cable |

| Color | Customized |

| Warranty | One Year |

| Options | Large diameter capacity |

| Motorized traveling wheels basis | |

| Wireless hand control box |

✧ Spare Parts Brand

For international business, Weldsuccess use all the famous spare parts brand to ensure the welding rotators with long time using life. Even the spare parts broken after years later, the end user also can replace the spare parts easily at the local market.

1.Frequency changer is from Damfoss brand.

2.Motor is from Invertek or ABB brand.

3.Electric elements is Schneider brand.

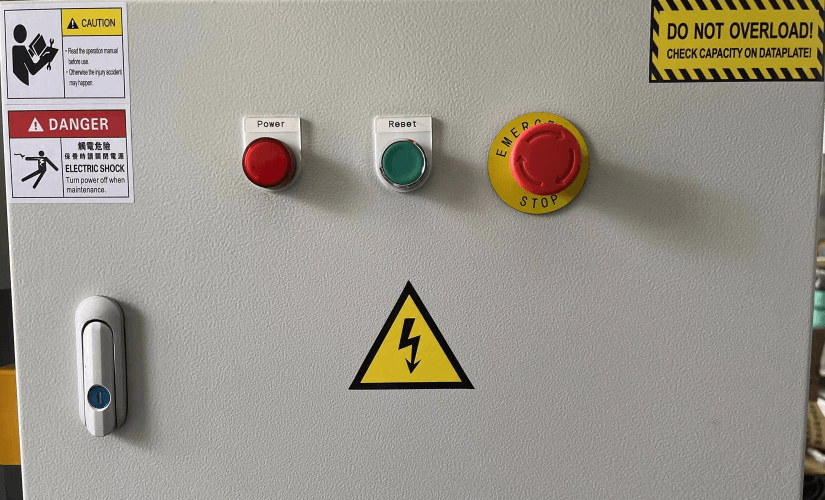

✧ Control System

1.Hand control box with Rotation speed display, Forward , Reverse, Power Lights and Emergency Stop functions.

2.Main electric cabinet with power switch,Power Lights, Alarm , Reset functions and Emergency Stop functions.

3.Foot pedal to control the rotation direction.

4.Wireless hand control box is available if needed.

✧ Production Progress

WELDSUCCESS as a manufacturer, we produce the welding rotators from the original steel plates cutting, welding, mechanical treatment, drill holes, assembly, painting and final testing.

In this way, we will control all the production process is under our ISO 9001:2015 quality management system. And ensure our customer will receive a high quality products.

✧ Previous Projects