3-Ton Welding Positioner with Chuck

✧ Introduction

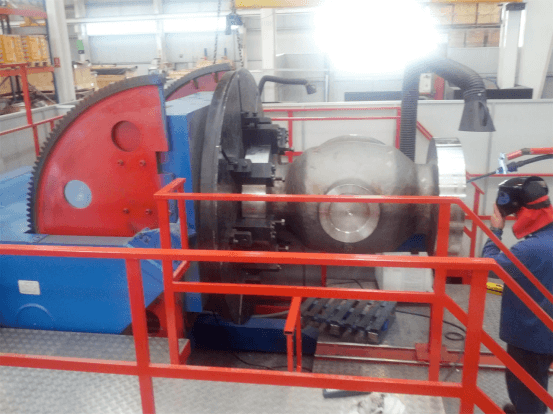

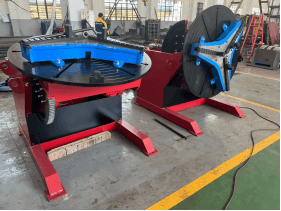

3-ton welding positioner is a specialized piece of equipment designed to facilitate the precise positioning and rotation of workpieces weighing up to 3 metric tons (3,000 kg) during welding processes. This equipment enhances accessibility and ensures high-quality welds, making it invaluable in various fabrication and manufacturing settings.

Key Features and Capabilities

Load Capacity:

Supports workpieces with a maximum weight of 3 metric tons (3,000 kg).

Suitable for medium to large components across several industrial applications.

Rotation Mechanism:

Features a robust turntable that allows for smooth and controlled rotation of the workpiece.

Driven by electric or hydraulic motors, ensuring reliable and efficient operation.

Tilt Capability:

Many models include a tilting function, enabling adjustments to the angle of the workpiece.

This feature enhances accessibility for welders and ensures optimal positioning for various welding processes.

Precise Speed and Position Control:

Equipped with advanced control systems that allow for accurate adjustments to speed and position.

Variable speed controls facilitate tailored operation based on the specific welding task.

Stability and Rigidity:

Constructed with a strong frame designed to withstand the loads and stresses associated with handling 3-ton workpieces.

Reinforced components ensure stability and reliability during operation.

Integrated Safety Features:

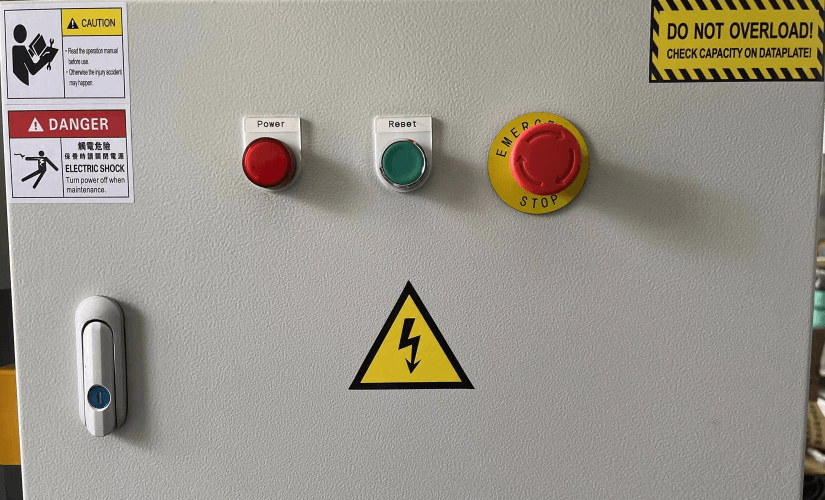

Safety mechanisms such as emergency stop buttons, overload protection, and safety guards enhance operational safety.

Designed to create a secure working environment for operators.

Versatile Applications:

Ideal for a variety of welding tasks, including:

Heavy machinery assembly

Structural steel fabrication

Pipeline construction

General metalworking and repair tasks

Seamless Integration with Welding Equipment:

Compatible with various welding machines, including MIG, TIG, and stick welders, facilitating a smooth workflow during operations.

Benefits

Enhanced Productivity: The ability to easily position and rotate workpieces reduces manual handling and improves overall workflow efficiency.

Improved Weld Quality: Proper positioning and angle adjustments contribute to higher-quality welds and better joint integrity.

Reduced Operator Fatigue: Ergonomic features and ease of use minimize physical strain on welders, enhancing comfort during long welding sessions.

3-ton welding positioner is essential for workshops and industries that require precise handling and positioning of medium-sized components during welding operations. If you have any specific questions or need further information regarding this equipment, feel free to ask!

✧ Main Specification

| Model | VPE-3 |

| Turning Capacity | 3000kg maximum |

| Table diameter | 1400 mm |

| Rotation motor | 1.5 kw |

| Rotation speed | 0.05-0.5 rpm |

| Tilting motor | 2.2 kw |

| Tilting speed | 0.23 rpm |

| Tilting angle | 0~90°/ 0~120 °degree |

| Max. Eccentric distance | 200 mm |

| Max. Gravity distance | 150 mm |

| Voltage | 380V±10% 50Hz 3Phase |

| Control system | Remote control 8m cable |

| Options | Welding chuck |

| Horizontal table | |

| 3 axis hydraulic positioner |

✧ Spare Parts Brand

All our spare parts are from international famous company, and it will ensure the end user can replace the spare parts easily at their local market.

1. Frequency changer is from Danfoss brand.

2. Motor is from Invertek or ABB brand.

3. Electric elements is Schneider brand.

✧ Control System

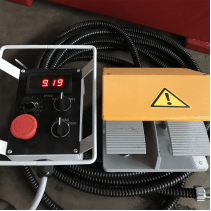

1.Hand control box with Rotation speed display, Rotation Forward , Rotation Reverse, Tilting Up, Tilting Down, Power Lights and Emergency Stop functions.

2.Main electric cabinet with power switch,Power Lights, Alarm , Reset functions and Emergency Stop functions.

3.Foot pedal to control the rotation direction.

✧ Production Progress

From 2006, and based on ISO 9001:2015 quality management system, we control our equipment quality from the original steel plates,each production progress all with inspector to control it. This also help us get more and more business from the international market.

Till now, all of our products with CE approval to European market. Hope our products will give you a help for your projects production.

✧ Previous Projects