600kg Welding Positioner

✧ Introduction

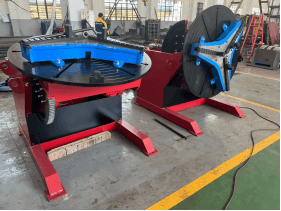

600kg welding positioner is a specialized piece of equipment used in welding operations to position and rotate workpieces. It is designed to handle workpieces weighing up to 600 kilograms (kg) or 0.6 metric tons, providing stability and controlled movement during welding processes.

Here are some key features and characteristics of a 600kg welding positioner:

Load Capacity: The positioner is capable of supporting and rotating workpieces with a maximum weight capacity of 600kg. This makes it suitable for handling small to medium-sized workpieces in welding applications.

Rotation Control: The welding positioner typically includes a control system that allows operators to control the rotation speed and direction. This enables precise control over the positioning and movement of the workpiece during welding operations.

Adjustable Positioning: The positioner often features adjustable positioning options, such as tilting, rotating, and height adjustment. These adjustments allow for optimal positioning of the workpiece, ensuring easy access to weld joints and improving welding efficiency.

Sturdy Construction: The positioner is typically made of sturdy materials to ensure stability and durability during operation. It is designed to provide a secure platform for welding processes, ensuring the workpiece remains steady and properly aligned.

Compact Design: A 600kg welding positioner is usually compact in size, making it suitable for smaller workspaces or applications where space is limited. Its compact design allows for easy maneuverability and integration into existing welding setups.

The 600kg welding positioner is commonly used in various industries, including fabrication shops, automotive manufacturing, and light to medium-duty welding operations. It assists in achieving accurate and efficient welding by providing controlled positioning and rotation of workpieces.

✧ Main Specification

| Model | HBJ-06 |

| Turning Capacity | 600kg maximum |

| Table diameter | 1000 mm |

| Rotation motor | 0.75 kw |

| Rotation speed | 0.09-0.9 rpm |

| Tilting motor | 0.75 kw |

| Tilting speed | 1.1 rpm |

| Tilting angle | 0~90°/ 0~120 °degree |

| Max. Eccentric distance | 150 mm |

| Max. Gravity distance | 100 mm |

| Voltage | 380V±10% 50Hz 3Phase |

| Control system | Remote control 8m cable |

| Options | Welding chuck |

| Horizontal table | |

| 3 axis positioner |

✧ Spare Parts Brand

For international business, Weldsuccess use all the famous spare parts brand to ensure the welding rotators with long time using life. Even the spare parts broken after years later, the end user also can replace the spare parts easily at the local market.

1.Frequency changer is from Damfoss brand.

2.Motor is from Invertek or ABB brand.

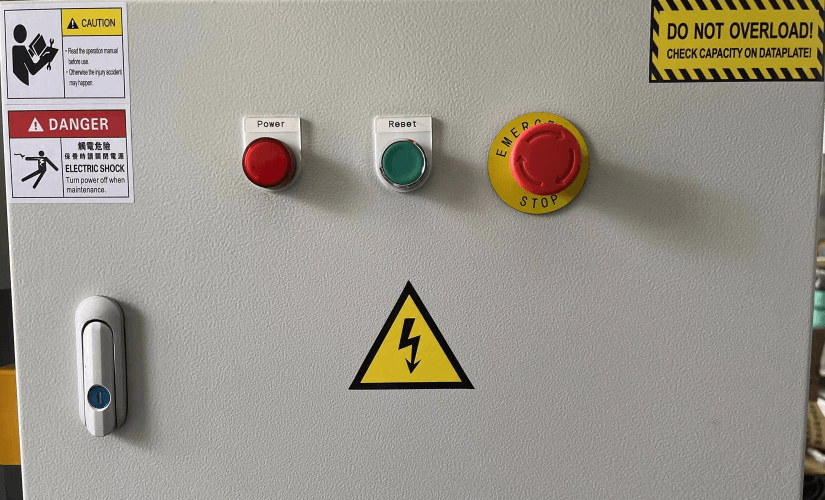

3.Electric elements is Schneider brand.

✧ Control System

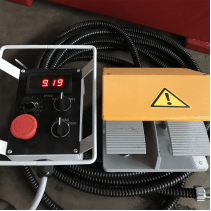

1.Hand control box with Rotation speed display, Rotation Forward , Rotation Reverse, Tilting Up, Tilting Down, Power Lights and Emergency Stop functions.

2.Main electric cabinet with power switch,Power Lights, Alarm , Reset functions and Emergency Stop functions.

3.Foot pedal to control the rotation direction.

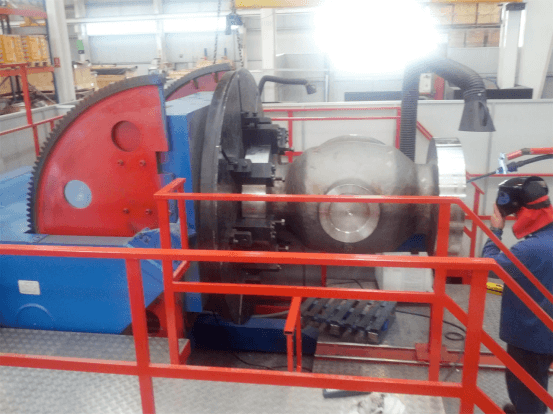

✧ Production Progress

WELDSUCCESS as a manufacturer, we produce the welding positioner from the original steel plates cutting, welding, mechanical treatment, drill holes, assembly, painting and final testing.

In this way, we will control all the production process is under our ISO 9001:2015 quality management system. And ensure our customer will receive a high quality products.

✧ Previous Projects