AHVPE-10 Height Adjustment Welding Positioner

✧ Introduction

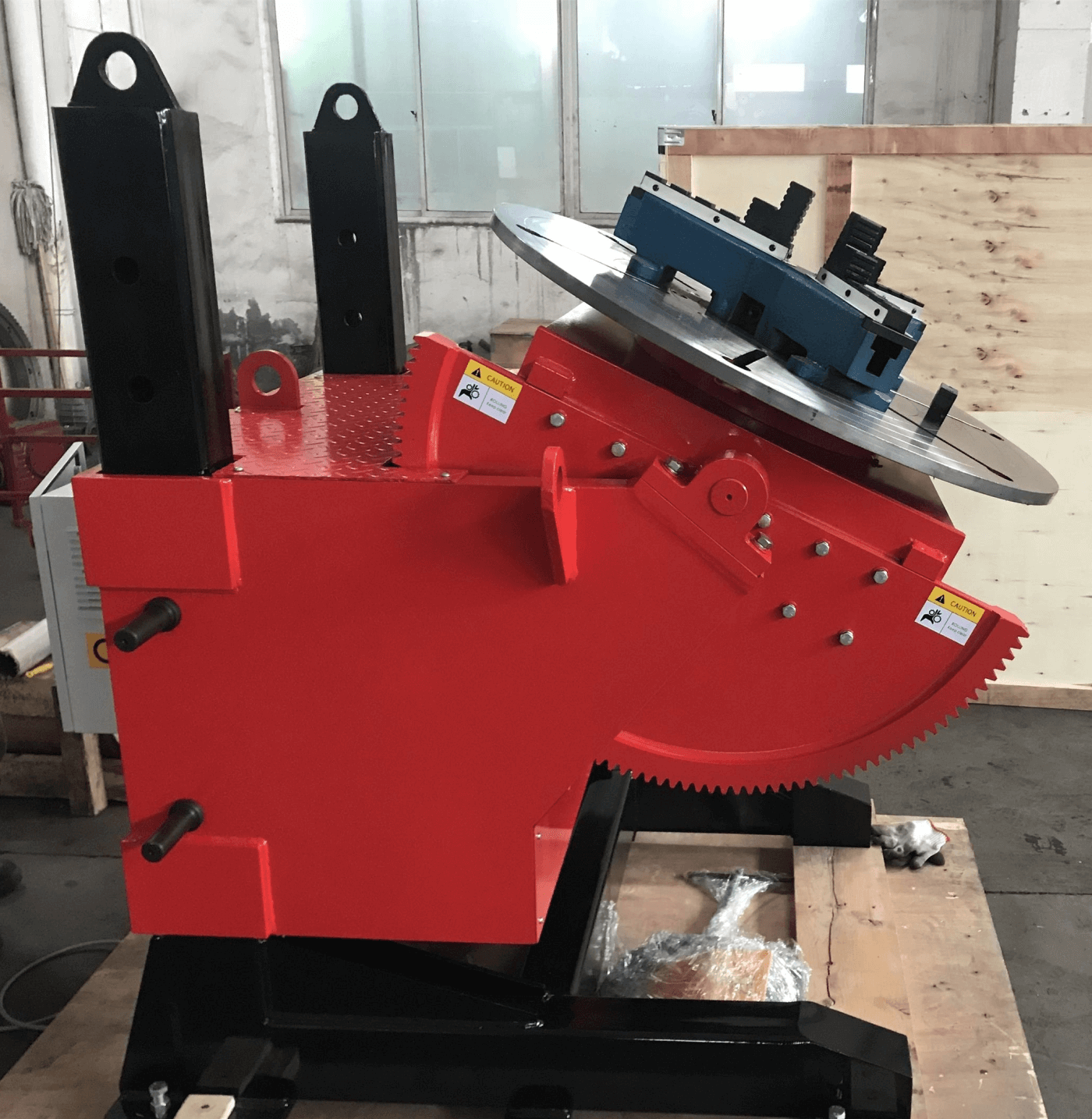

Height adjustment 2 axis gear tilt welding Positioner is a basic solution for tilting and rotation of the work pieces. It can adjust the center height according to different size workpieces.

The worktable could be rotated ( in 360°) or tilted (in 0 – 90°) allowing work piece to be welded at the best position,and motorized rotation speed is VFD control.

During our workshop fabrication, sometimes we have bigger size workpiece, at this time we will need the welding positioner with higher center height. Then the height adjustment welding positioner will be helpfu. It can adjust the height by manual bolt. Customer can adjust the positioner height according to the different work pieces.

The height adjust welding positioner actually with 3 axis, one is for rotation with speed adjustable. One is for tilting, tilting angle can be 0- 135 degree maximum. The last axis is for vertical height adjust.

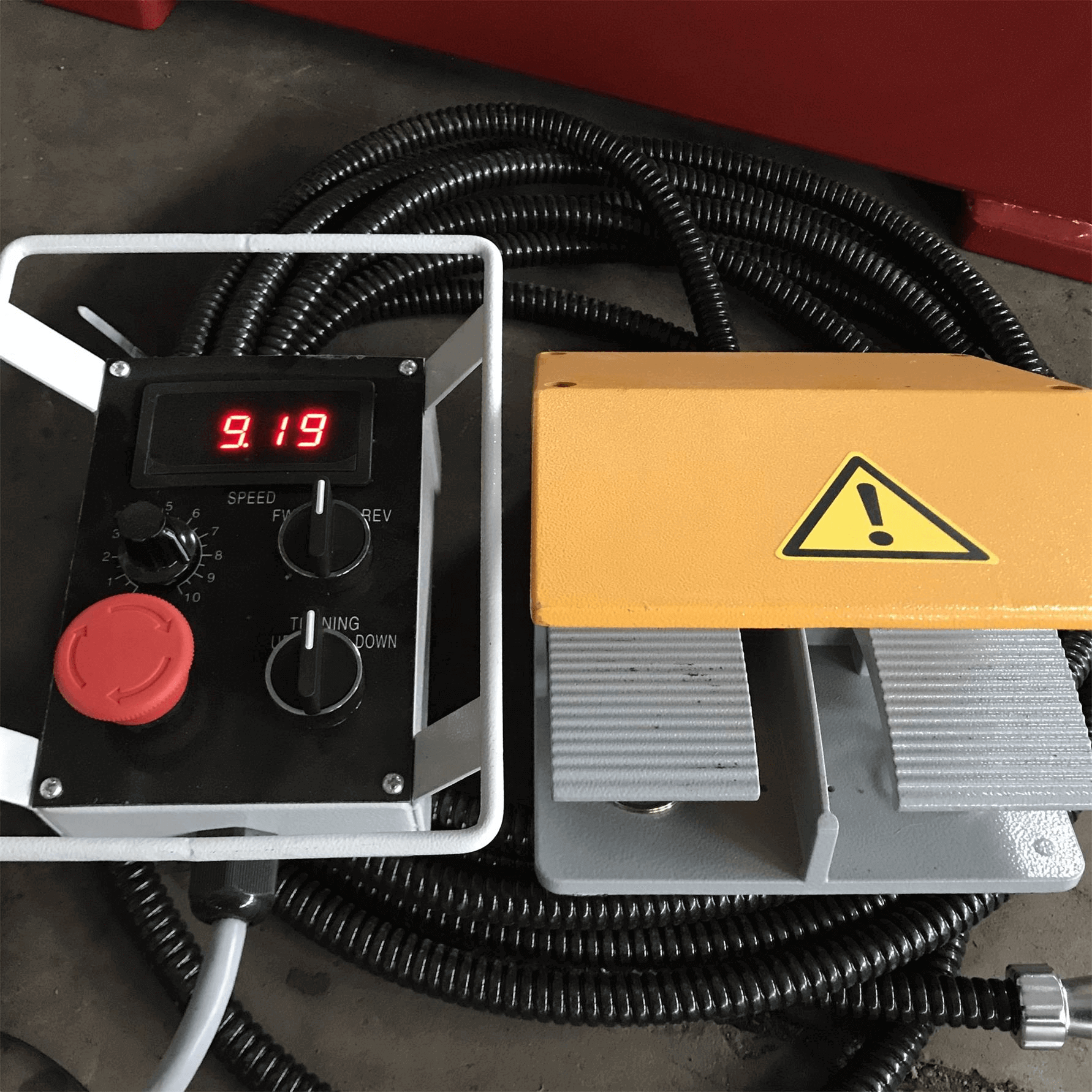

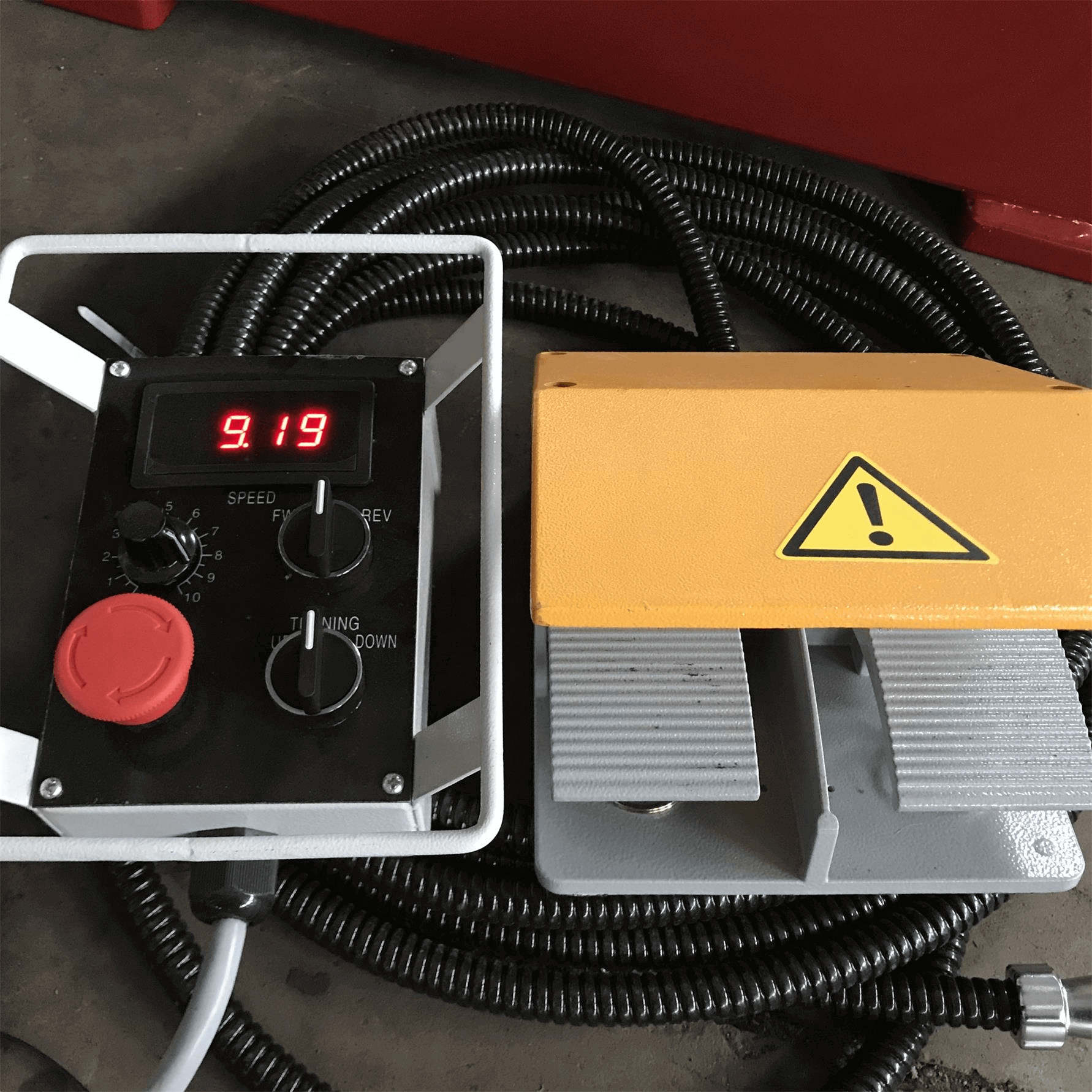

During welding, the table turning speed is adjustable,we can adjust slower or faster as we needed. The rotation direction also can be controlled by foot pedal, much more convenient for workers during welding.

Three jaw linkage welding chucks is also available for different pipe diameters, Weldsuccess will install the welding chucks ready before delivery. When the end user receive the cargo, can use it directly.

✧ Main Specification

| Model | AHVPE-10 |

| Turning Capacity | 1000kg maximum |

| Table diameter | 1000 mm |

| Center height adjust | Manual by bolt / Hydraulic |

| Rotation motor | 0.75 kw |

| Rotation speed | 0.05-0.5 rpm |

| Tilting motor | 1.1 kw |

| Tilting speed | 0.67 rpm |

| Tilting angle | 0~90°/ 0~120 °degree |

| Max. Eccentric distance | 150 mm |

| Max. Gravity distance | 100 mm |

| Voltage | 380V±10% 50Hz 3Phase |

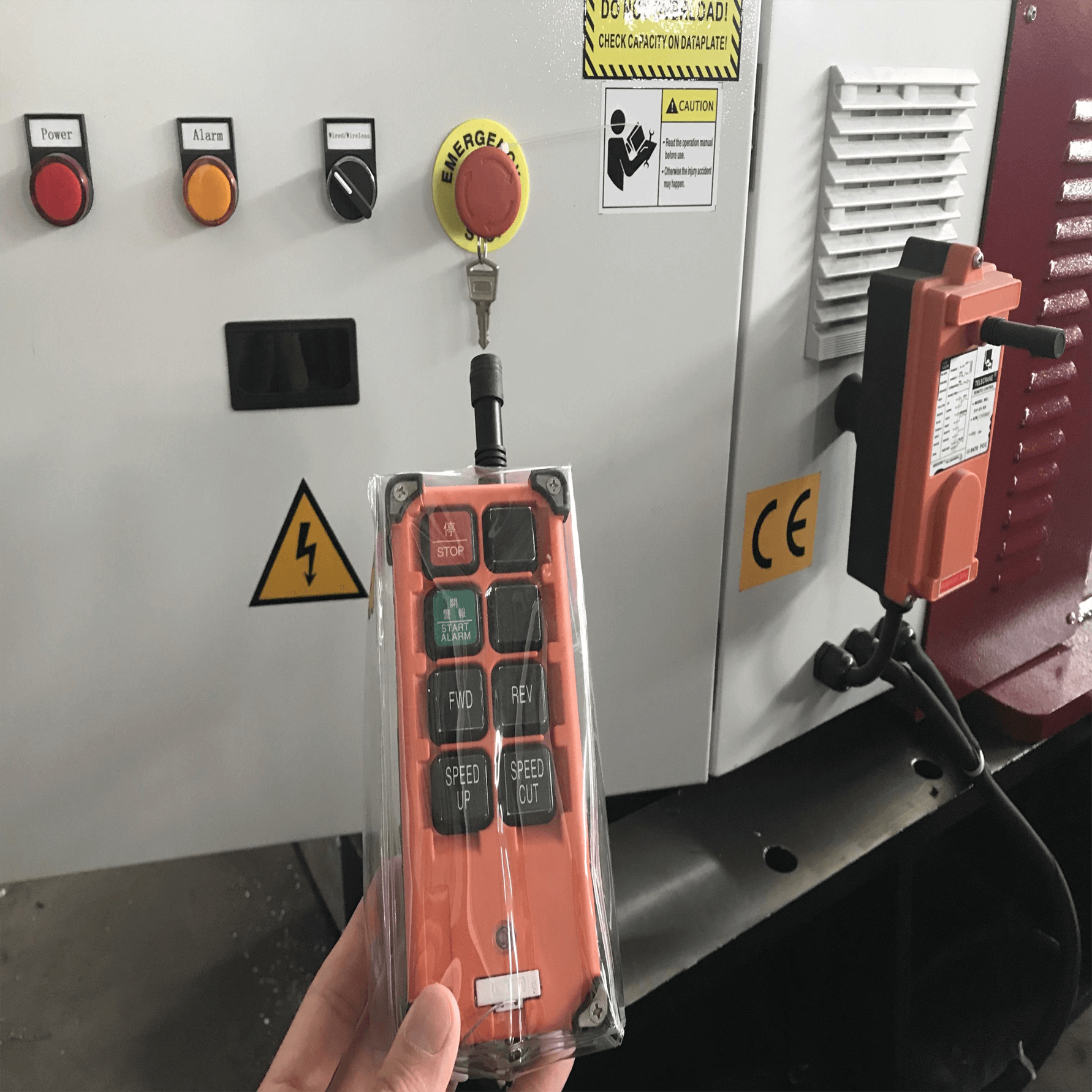

| Control system | Remote control 8m cable |

| Options | Welding chuck |

| Horizontal table | |

| 3 axis hydraulic positioner |

✧ Spare Parts Brand

For international business, Weldsuccess use all the famous spare parts brand to ensure the welding rotators with long time using life. Even the spare parts broken after years later, the end user also can replace the spare parts easily at the local market.

1.Frequency changer is from Damfoss brand.

2.Motor is from Invertek or ABB brand.

3.Electric elements is Schneider brand.

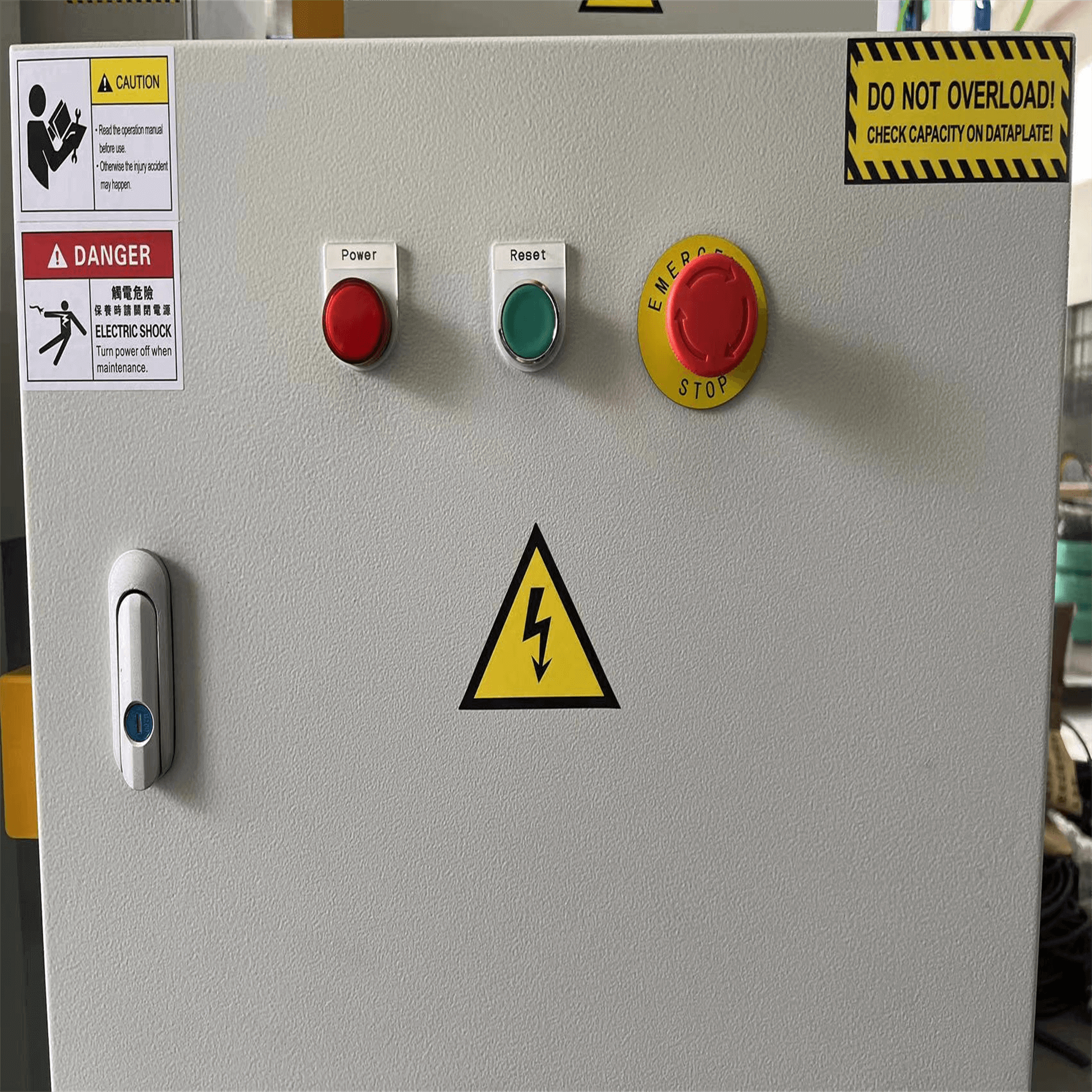

✧ Control System

1.Normally the welding positioner with hand control box and foot switch.

2.One hand box, the worker can control Rotation Forward, Rotation Reverse, Emergency Stop functions, and also have the rotation speed display and power lights.

3.All the welding positioner electric cabinet made by Weldsuccess Ltd itself. The main electric elements are all from Schneider.

4.Sometimes we did the welding positioner with PLC control and RV gearboxes, which can be work together with robot as well.

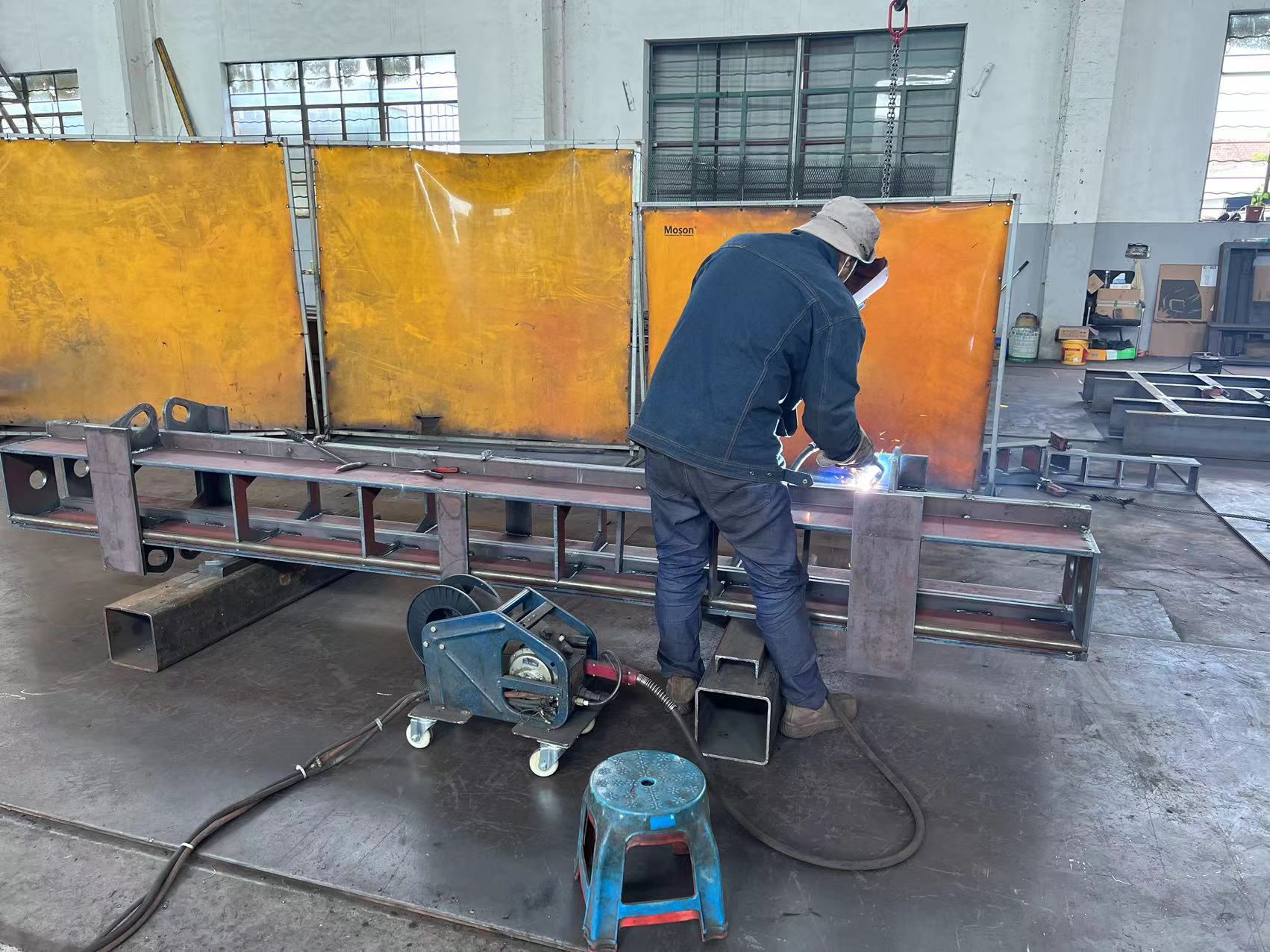

✧ Production Progress

WELDSUCCESS as a manufacturer, we produce the welding rotators from the original steel plates cutting, welding, mechanical treatment, drill holes, assembly, painting and final testing.

In this way, we will control all the production process is under our ISO 9001:2015 quality management system. And ensure our customer will receive a high quality products.

✧ Previous Projects