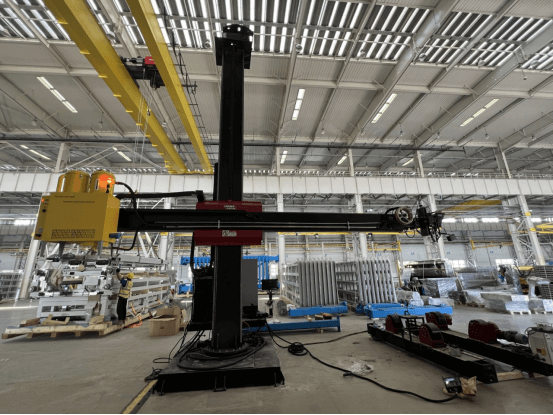

Column Boom with Self aligning welding rotator

✧ Introduction

A column boom with a self-aligning welding rotator is a comprehensive welding system that combines a sturdy column-mounted boom structure with a high-capacity, self-aligning welding rotator. This integrated system provides enhanced flexibility, positioning capabilities, and automated alignment for welding large and heavy workpieces.

Key features and characteristics of a column boom with a self-aligning welding rotator include:

- Column Boom Structure:

- Robust and stable column-mounted design to support the weight and movement of the boom and rotator assembly.

- Vertical adjustment capabilities to accommodate different workpiece heights.

- Horizontal reach and positioning provided by the boom arm.

- Smooth and precise movement of the boom to access various areas of the workpiece.

- Self-Aligning Welding Rotator:

- Capable of handling workpieces up to 20 metric tons or more.

- Automatic self-alignment feature to maintain proper positioning and orientation of the workpiece during rotation.

- Precise control over rotation speed and direction for consistent welding quality.

- Integrated tilt and height adjustment functions for optimal positioning.

- Integrated Control System:

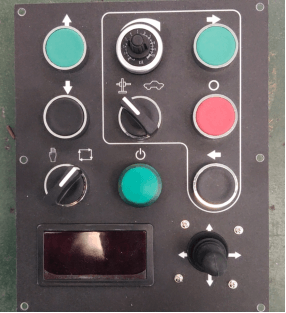

- Centralized control panel to manage the operation of the column boom and welding rotator.

- Automated features for synchronizing the movement and alignment of the boom and rotator.

- User-friendly interface for setting parameters, monitoring, and controlling the welding process.

- Enhanced Productivity and Weld Quality:

- Streamlined setup and positioning of large workpieces, reducing manual labor and preparation time.

- Consistent and uniform welding quality through the self-aligning capabilities of the rotator.

- Improved efficiency and productivity in welding operations, especially for heavy-duty components.

- Safety Features:

- Robust construction and safety interlocks to protect the operator and the equipment.

- Emergency stop mechanisms and overload protection to ensure safe operation.

The column boom with a self-aligning welding rotator is commonly used in industries such as shipbuilding, heavy machinery manufacturing, pressure vessel fabrication, and large-scale construction projects. It provides a versatile and automated solution for handling and welding of heavy-duty workpieces, enabling greater precision, consistency, and productivity in welding operations.

If you have any specific requirements or questions regarding the column boom with a self-aligning welding rotator, please email us, and I'll be happy to assist you further.

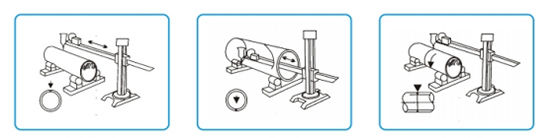

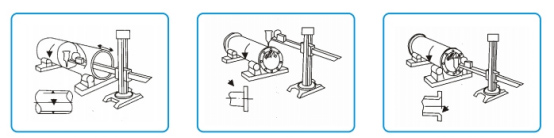

1.Welding column boom are widely used for wind tower, pressure vessels and tanks outside and inside longitudinal seam welding or girth welding. It will be realize the automatic welding when using together with our welding rotators system.

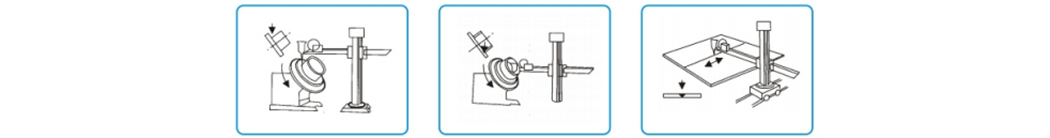

2.Using together with welding positioners will be more convenient to welding the flanges as well.

3.According to the work pieces length, we also make the column boom with traveling wheels basis. So it also available for welding long longitudinal seam welding.

4.On the welding column boom, we can install the MIG power source, SAW power source and AC/DC tandem power source as well.

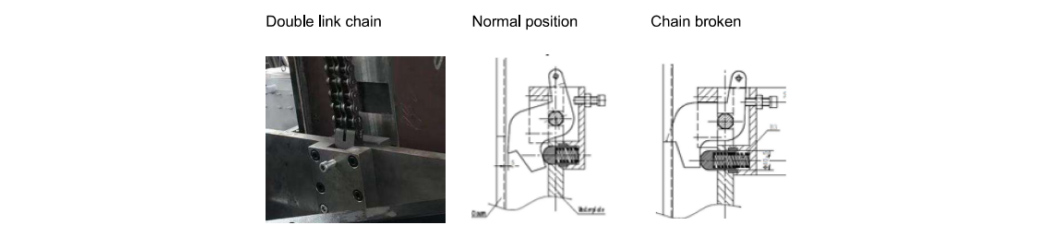

5.The welding column boom system is lifting by double link chain. It also with anti-falling system to ensure the using safety even the chain broken.

6.Flux recovery machine, welding camera monitor and laser pointer are all available to realize the automatic welding. You can email us for the working video.

✧ Main Specification

| Model | MD 3030 C&B |

| Boom end load capacity | 250kg |

| Vertical boom travel | 3000 mm |

| Vertical boom speed | 1100 mm/min |

| Horizontal boom travel | 3000 mm |

| Horizontal boon speed | 175-1750 mm/min VFD |

| Boom end cross slide | Motorized 150*150 mm |

| Rotation | ±180°Manual with lock |

| Traveling way | Motorized traveling |

| Voltage | 380V±10% 50Hz 3Phase |

| Control system | Remote control10m cable |

| Color | RAL 3003 RED+9005 Black |

| Options-1 | Laser pointer |

| Options -2 | Camera monitor |

| Options-3 | Flux recovery machine |

✧ Spare Parts Brand

1.The column elevator brake motor and boom variable frequency motor is from Invertek with fully CE approval.

2.The Variable Frequency Driver is from Schneider or Danfoss, with both CE and UL approval.

3.All the welding column boom spare parts are easily to replace if have accident broken few years later at the end user local market.

✧ Control System

1.The column boom elevator with anti-falling system to ensure the working safety. All the column boom tested the anti-falling system before delivery to end user.

2.Traveling carriage also with traveling safety hook on the rails together to ensure the traveling no falling.

3.Each column boom all with power source platform.

4.Flux recovery machine and power source are can be integrated together.

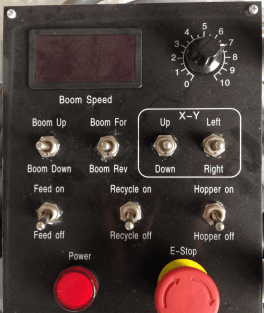

5.The column boom with one remote hand control box to control boom up / down/ move forward and backward and traveling forward and backward.

6.If the column boom with SAW power source integrated, the remote hand box also with function of welding start, welding stop,wire feed and wire back etc.

✧ Previous Projects

WELDSUCCESS as a manufacturer, we produce the welding column boom from the original steel plates cutting, welding, mechanical treatment, drill holes, assembly, painting and final testing.

In this way, we will control all the production process is under our ISO 9001:2015 quality management system. And ensure our customer will receive a high quality products.