SAR-80 Self Aligning Welding Rotator

✧ Introduction

80-ton self-aligning welding rotator is a specialized piece of equipment designed for the precise rotation and positioning of heavy workpieces weighing up to 80 metric tons (80,000 kg) during welding operations. The self-aligning feature allows the rotator to automatically adjust the position of the workpiece to ensure optimal alignment for welding, enhancing both efficiency and quality.

Key Features and Capabilities

Load Capacity:

Designed to handle workpieces with a maximum weight of 80 metric tons (80,000 kg).

Suitable for heavy-duty applications in various industries.

Self-Aligning Mechanism:

The self-aligning design automatically adjusts to the workpiece’s position, ensuring optimal alignment for welding.

Reduces the need for manual adjustments, improving efficiency and precision.

Robust Rotational Mechanism:

Features a heavy-duty turntable or roller system that provides smooth and controlled rotation.

Driven by powerful electric motors or hydraulic systems for reliable performance.

Precise Speed and Position Control:

Equipped with advanced control systems that allow for precise adjustments to the speed and position of the workpiece.

Includes variable speed drives and digital controls for accurate positioning.

Stability and Rigidity:

Constructed with a sturdy frame to withstand the significant loads and stresses associated with handling 80-ton workpieces.

Reinforced components ensure stability during operation.

Integrated Safety Features:

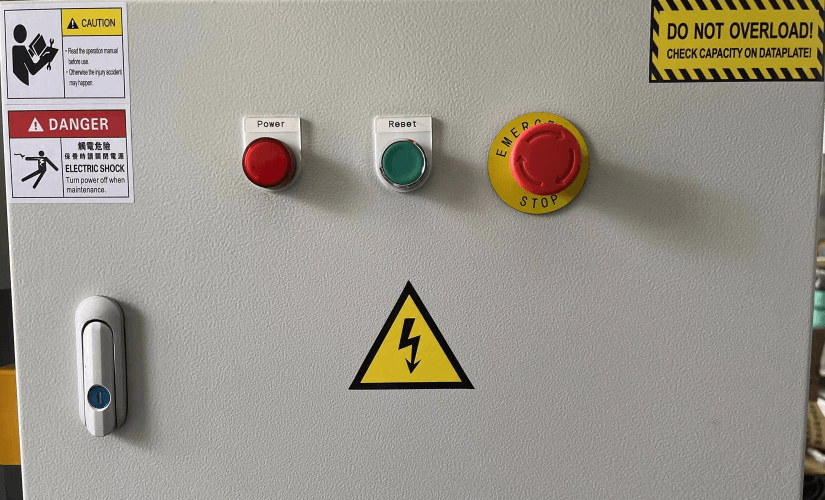

Safety mechanisms include emergency stop buttons, overload protection, and safety interlocks to prevent accidents.

Designed to maintain a secure working environment for operators.

Seamless Integration with Welding Equipment:

Compatible with various welding machines, including MIG, TIG, and submerged arc welders, facilitating a smooth workflow during welding operations.

Versatile Applications:

Ideal for a variety of applications, including:

Shipbuilding and repair

Heavy machinery manufacturing

Fabrication of large pressure vessels

Structural steel assembly

Benefits

Enhanced Productivity: The self-aligning feature reduces setup time and manual handling, improving overall workflow efficiency.

Improved Weld Quality: Optimal alignment and positioning contribute to high-quality welds and better joint integrity.

Reduced Labor Costs: Automation of alignment and rotation minimizes the need for additional labor, lowering production costs.

The 80-ton self-aligning welding rotator is essential for industries that require precise handling and welding of large components, ensuring safety, efficiency, and high-quality results in welding operations. If you have any specific questions or need further information about this equipment, feel free to ask!

✧ Main Specification

| Model | SAR-80 Welding Roller |

| Turning Capacity | 80 tons maximum |

| Loading Capacity-Drive | 40 tons maximum |

| Loading Capacity-Idler | 40 tons maximum |

| Vessel size | 500~6000mm |

| Adjust Way | Self aligning roller |

| Motor Rotation Power | 2*4KW |

| Rotation Speed | 100-1000mm/min Digital display |

| Speed control | Variable frequency driver |

| Roller wheels | Steel coated with PU type |

| Control system | Remote hand control box & Foot pedal switch |

| Color | RAL3003 RED & 9005 BLACK / Customized |

| Options | Large diameter capacity |

| Motorized traveling wheels basis | |

| Wireless hand control box |

✧ Spare Parts Brand

For international business, Weldsuccess use all the famous spare parts brand to ensure the welding rotators with long time using life. Even the spare parts broken after years later, the end user also can replace the spare parts easily at the local market.

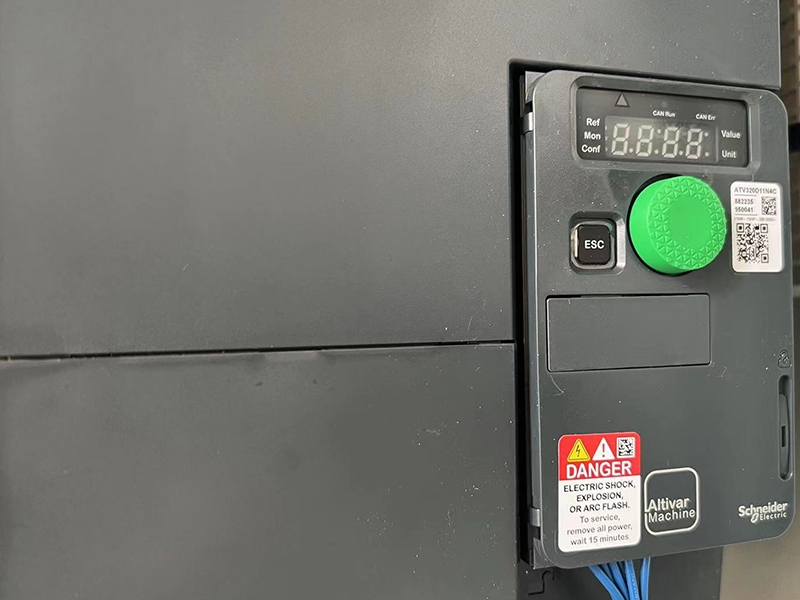

1.Frequency changer is from Damfoss brand.

2.Motor is from Invertek or ABB brand.

3.Electric elements is Schneider brand.

✧ Control System

1.Remote Hand control box with Rotation speed display, Forward , Reverse, Power Lights and Emergency Stop functions, which will be easy for work to control it.

2.Main electric cabinet with power switch,Power Lights, Alarm , Reset functions and Emergency Stop functions.

3.Wireless hand control box is available in 30m signal receiver.

✧ Production Progress

WELDSUCCESS as a manufacturer, we produce the welding rotators from the original steel plates cutting, welding, mechanical treatment, drill holes, assembly, painting and final testing.

In this way, we will control all the production process is under our ISO 9001:2015 quality management system. And ensure our customer will receive a high quality products.

Till now, we export our welding rotators to USA, UK, ITLAY, SPAIN, HOLLAND, THAILAND, VIETNAM, DUBAI AND Saudi Arabia etc. More than 30 countries.

✧ Previous Projects