CR-10 Welding Rotator for pipe/tank welding

✧ Introduction

10-ton welding rotator is a heavy-duty device used in welding operations to position and rotate large and heavy workpieces. It is designed to handle substantial loads and provide stability and control during the welding process.

Here are some key features and characteristics of a 10-ton welding rotator:

- Load Capacity: The welding rotator has an impressive load capacity of 10 tons, meaning it can support and rotate workpieces weighing up to 10 tons.

- Rotational Capability: The rotator allows for controlled rotation of the workpiece. It can rotate the workpiece at different speeds and in various directions to accommodate welding requirements.

- Adjustable Positioning: Typically, the rotator has adjustable features such as tilt, height, and rotation axis alignment. These adjustments enable precise positioning of the workpiece, ensuring optimal access to all sides and angles for welding.

- Drive Mechanism: Welding rotators of this size often utilize robust drive mechanisms, such as powerful electric motors or hydraulic systems, to provide smooth and controlled rotation.

- Control System: The rotator is equipped with a control system that allows operators to adjust rotation speed, direction, and other parameters. This enables precise control over the welding process.

10-ton welding rotator is commonly used in heavy-duty welding applications and industries such as shipbuilding, oil and gas, and large-scale construction. It is suitable for welding massive structures, vessels, tanks, and other oversized workpieces.

Using a welding rotator of this capacity significantly improves the efficiency and safety of welding operations involving large and heavy workpieces. It provides stability, precise positioning, and controlled rotation, enabling welders to achieve high-quality welds consistently.

✧ Main Specification

| Model | CR- 10 Welding Roller |

| Turning Capacity | 10 tons maximum |

| Loading Capacity-Drive | 5 tons maximum |

| Loading Capacity-Idler | 5 tons maximum |

| Vessel size | 500~3500mm |

| Adjust Way | Bolt adjustment |

| Motor Rotation Power | 2*0.55 KW |

| Rotation Speed | 100-1000mm/min Digital display |

| Speed control | Variable frequency driver |

| Roller wheels | Steel coated with PU type |

| Control system | Remote hand control box & Foot pedal switch |

| Color | RAL3003 RED & 9005 BLACK / Customized |

| Options | Large diameter capacity |

| Motorized traveling wheels basis | |

| Wireless hand control box |

✧ Spare Parts Brand

For international business, Weldsuccess use all the famous spare parts brand to ensure the welding rotators with long time using life. Even the spare parts broken after years later, the end user also can replace the spare parts easily at the local market.

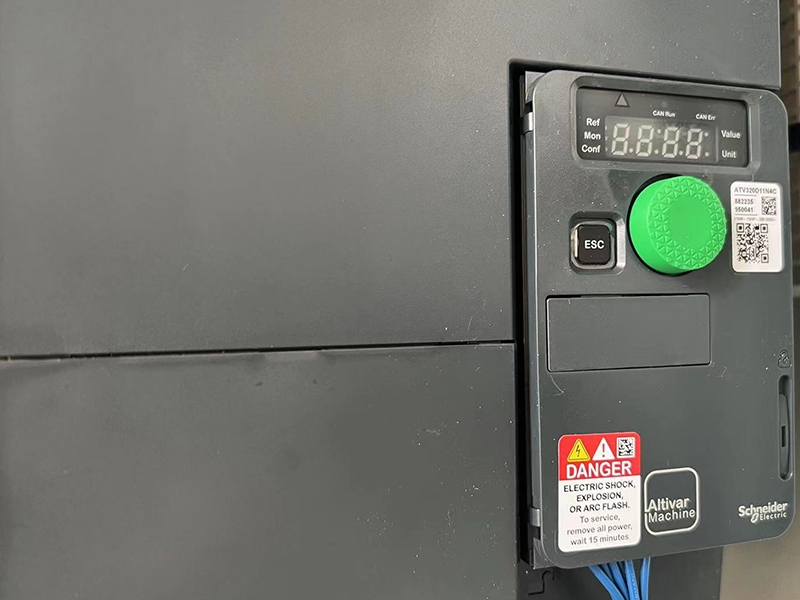

1.Frequency changer is from Damfoss brand.

2.Motor is from Invertek or ABB brand.

3.Electric elements is Schneider brand.

✧ Control System

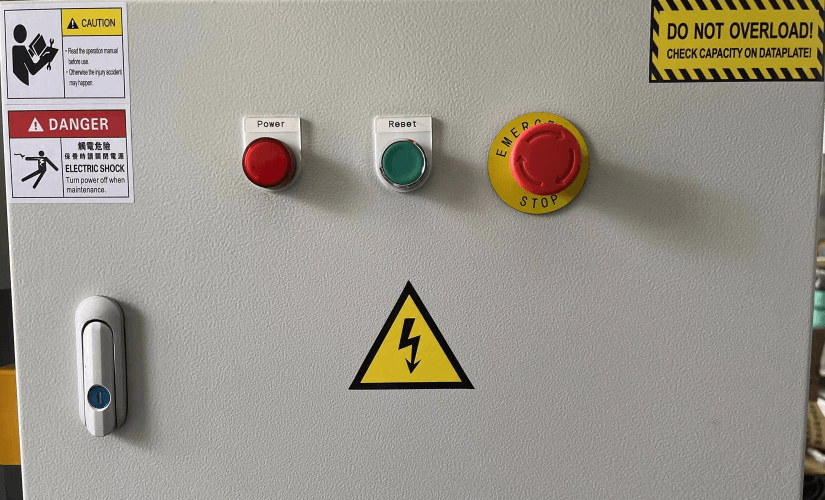

1.Hand control box with Rotation speed display, Forward , Reverse, Power Lights and Emergency Stop functions.

2.Main electric cabinet with power switch,Power Lights, Alarm , Reset functions and Emergency Stop functions.

3.Foot pedal to control the rotation direction.

4.Wireless hand control box is available if needed.

✧ Why Choose Us

Weldsuccess operate out of company-owned manufacturing facilities 25,000 sq ft of manufacturing & office space.

We export to 45 countries around the world and proud to have a large and growing list of customers, partners and distributors on 6 continents.

Our state of the art facility utilizes robotics and full CNC machining centers to maximize productivity, which is returned in value to customer through lower production costs.

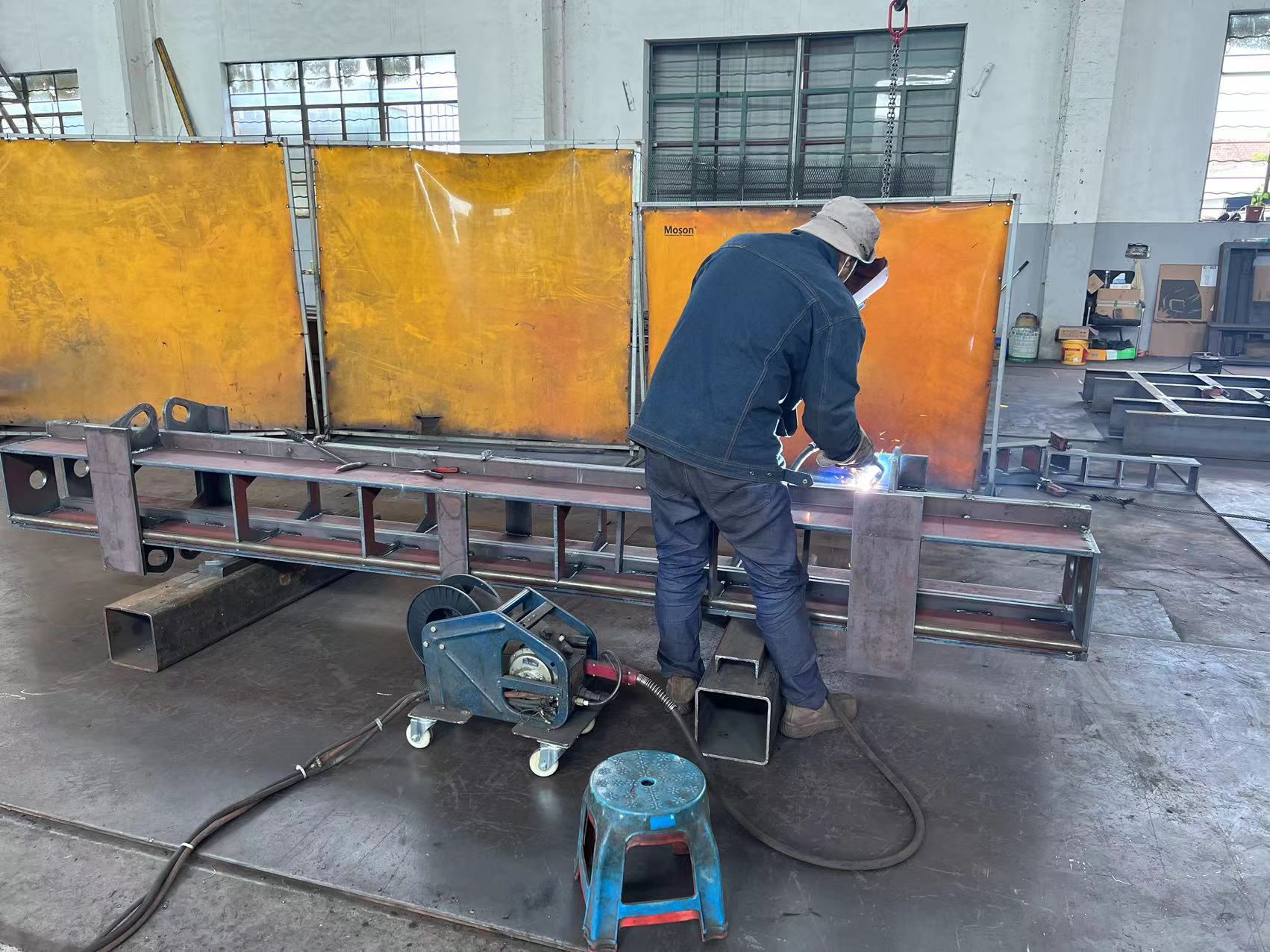

✧ Production Progress

Since 2006, we passed the ISO 9001:2015 quality management system, we control the quality from the original material steel plates. When our sales team proceed the order to production team, at the same time will reqeust the quality inspection from the original steel plate to final products progress. This will ensure our products meet the customers requirment.

At the same time, all of our products got the CE approval from 2012, so we can export to Europeam market freely.

✧ Previous Projects