CR-100 Heavy duty 100Ton Welding Rotator for Maximum 5500mm Diameter

✧ Introduction

1.100Ton load capacity welding rotators including one drive unit and one idler unit.

2.Normally we use Diameter 500mm and width 400mm PU wheels, Steel material roller wheels is available for customized.

3.With 2*3kw frequency variable motors, it will ensure the rotation more stable.

4.If the vessels with eccentricity, we will use the brake motor to increase the rotation torque.

5.Standard 100Ton welding rotator with vessels diameter 5500mm capacity, we also can customized for bigger size according to the end user request.

6.Fixed basis, motorized traveling wheels and fit up growing lines are all available from Weldsuccess Ltd.

✧ Main Specification

| Model | CR-100 Welding Roller |

| Turning Capacity | 100 ton maximum |

| Drive Load Capacity | 50 ton maximum |

| Idler Load Capacity | 50 ton maximum |

| Adjust Way | Bolt adjustment |

| Motor Power | 2*3kw |

| Vessel Diameter | 800~5000mm |

| Rotation Speed | 100-1000mm/min Digital display |

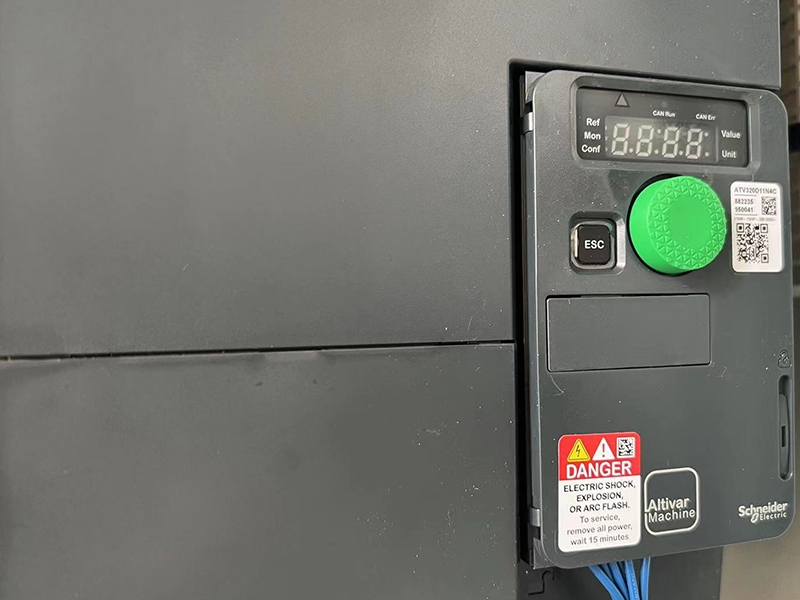

| Speed control | Variable frequency driver |

| Roller wheels | Steel coated with PU type |

| Control system | Remote hand control box & Foot pedal switch |

| Color | RAL3003 RED & 9005 BLACK / Customized |

|

Options |

Large diameter capacity |

| Motorized traveling wheels basis | |

| Wireless hand control box |

✧ Spare Parts Brand

1.Our 2 rotation reducer is heavy type with more than 9000Nm.

2.Both 3kw motors with fully CE approval to European market.

3.Controls electric elements are easily to find it at Schneider shop.

4.One remote hand control box or wireless hand box will be ship together.

✧ Control System

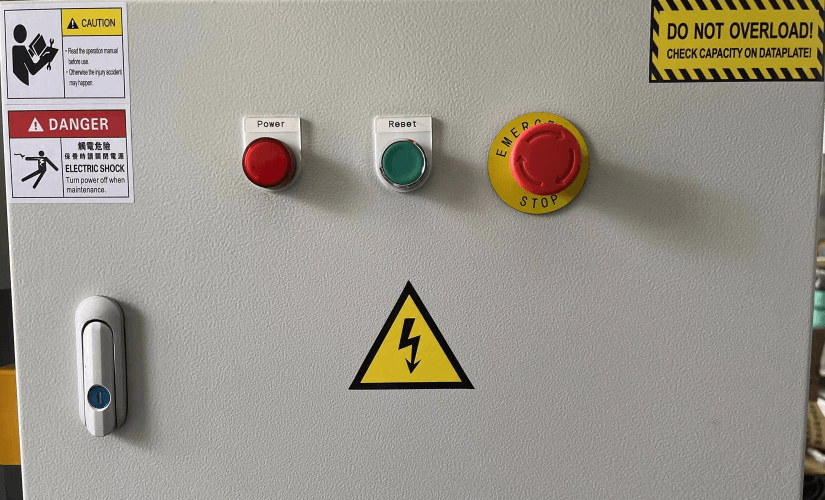

1.Nomally the welding rotator with one remote hand box to control the rotation direction and adjust the rotation speed.

2.Workers can adjust the rotation speed by a digital readout on the hand box. It will be easy to get the suitable rotation speed for workers.

3.For heavy type welding rotator, we also can supply the wireless hand

4.All the functions will be available on the remote hand control box, like Rotation speed display, Forward , Reverse, Power Lights and Emergency Stop etc.

✧ Production Progress

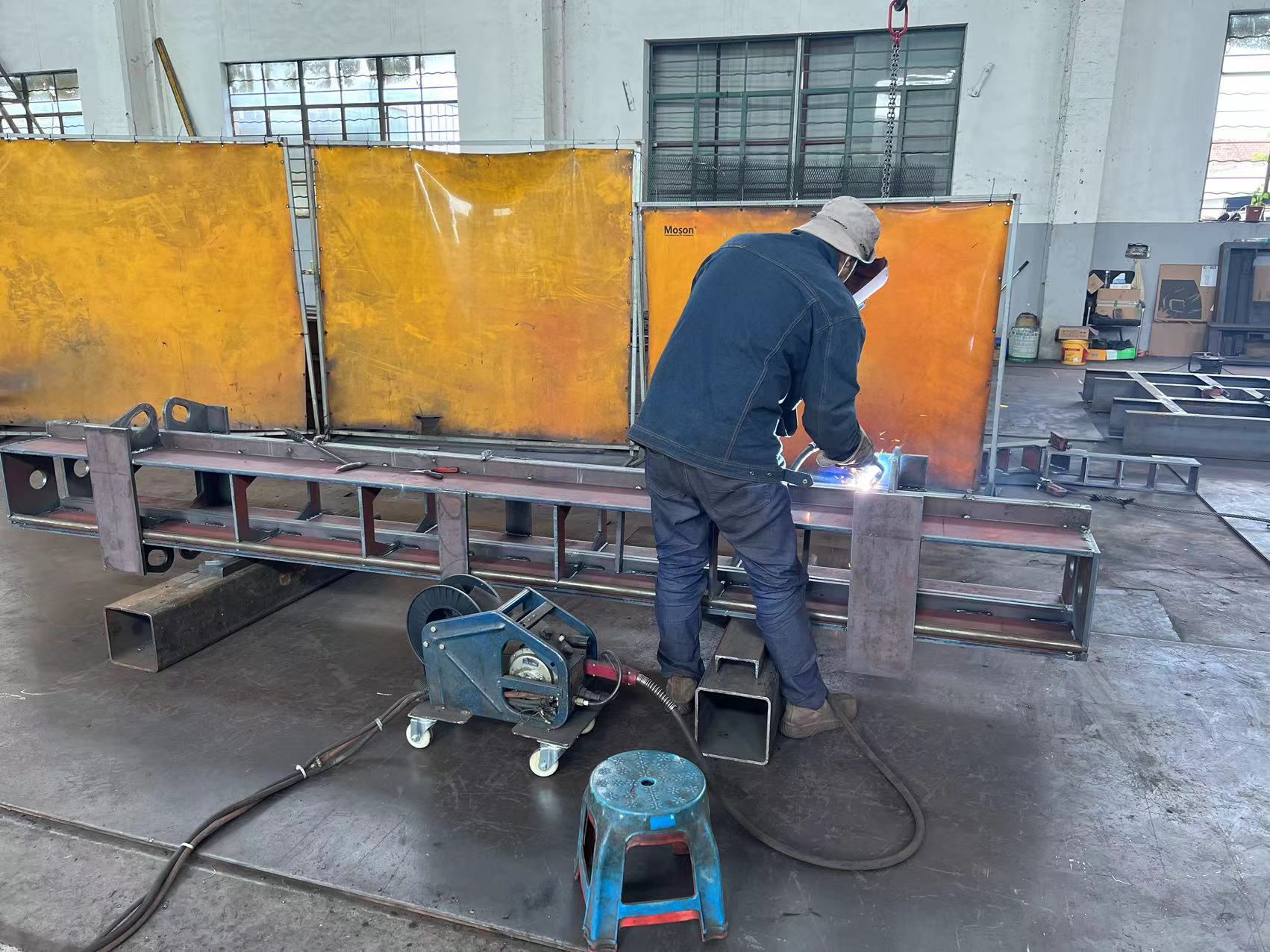

WELDSUCCESS as a manufacturer, we produce the welding rotators from the original steel plates cutting, welding, mechanical treatment, drill holes, assembly, painting and final testing.

In this way, we will control all the production process is under our ISO 9001:2015 quality management system. And ensure our customer will receive a high quality products.

✧ Previous Projects