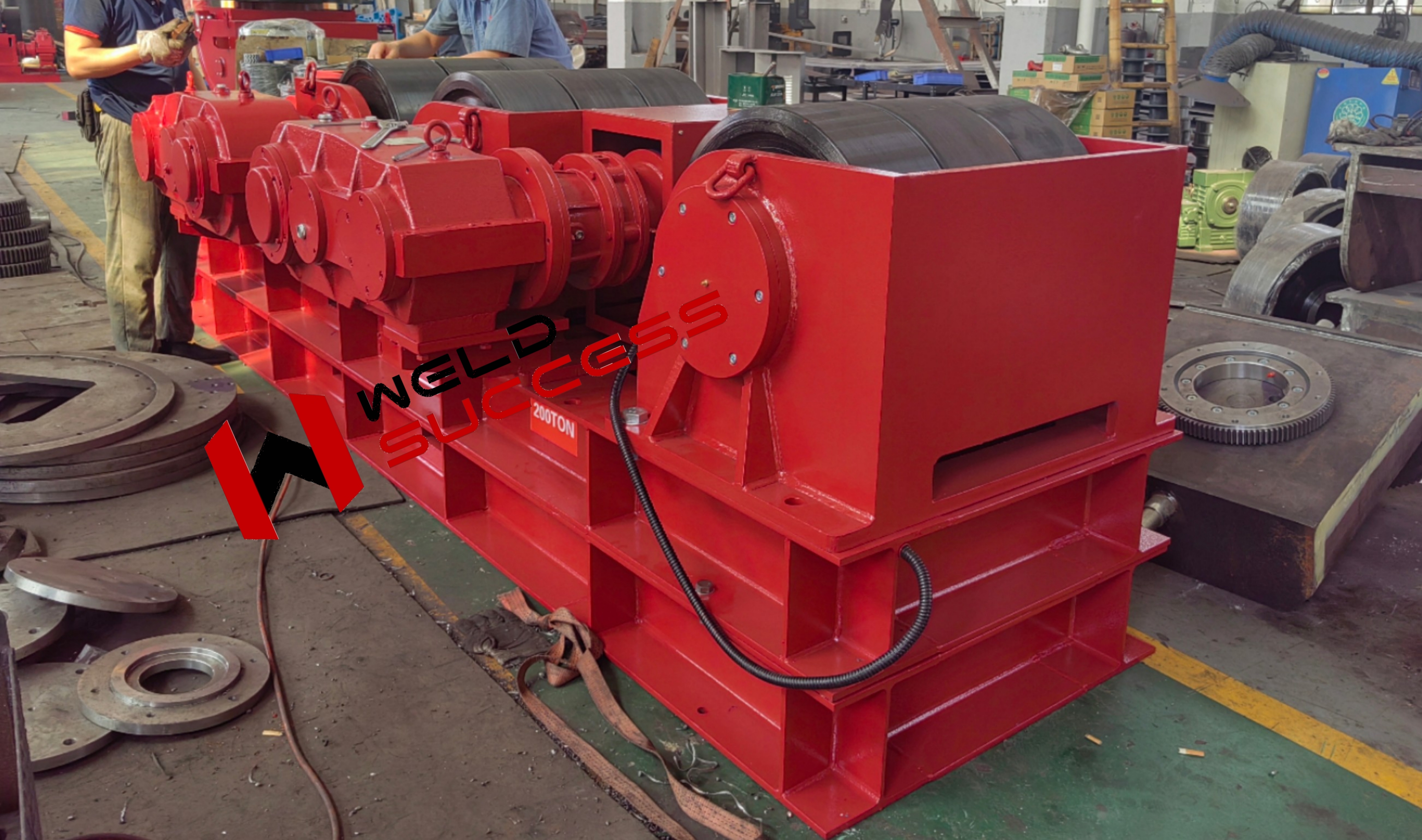

CR-300T Conventional Welding Rotator

✧ Introduction

300-ton welding rotator is a specialized piece of equipment designed for the controlled positioning and rotation of extremely large and heavy workpieces weighing up to 300 metric tons (300,000 kg) during welding operations.

Key features and capabilities of a 300-ton welding rotator include:

- Load Capacity:

- The welding rotator is engineered to handle and rotate workpieces with a maximum weight of 300 metric tons (300,000 kg).

- This immense load capacity makes it suitable for the fabrication and assembly of massive industrial structures, such as ship hulls, offshore platforms, and large-scale pressure vessels.

- Rotational Mechanism:

- The 300-ton welding rotator typically features a robust, heavy-duty turntable or rotational mechanism that provides the necessary support and controlled rotation for the incredibly large and heavy workpiece.

- The rotational mechanism may be driven by powerful motors, hydraulic systems, or a combination of both, ensuring smooth and precise rotation.

- Precise Speed and Position Control:

- The welding rotator is designed with advanced control systems that enable precise control over the speed and position of the rotating workpiece.

- This is achieved through features like variable speed drives, digital position indicators, and programmable control interfaces.

- Exceptional Stability and Rigidity:

- The welding rotator is constructed with a highly stable and rigid frame to withstand the immense loads and stresses associated with handling 300-ton workpieces.

- Reinforced foundations, heavy-duty bearings, and a sturdy base contribute to the overall stability and reliability of the system.

- Integrated Safety Systems:

- Safety is of paramount importance in the design of a 300-ton welding rotator.

- The system is equipped with comprehensive safety features, such as emergency stop mechanisms, overload protection, operator safeguards, and advanced sensor-based monitoring systems.

- Seamless Integration with Welding Equipment:

- The welding rotator is designed to seamlessly integrate with various high-capacity welding equipment, such as specialized heavy-duty welding machines, to ensure a smooth and efficient workflow during the fabrication of massive structures.

- Customization and Adaptability:

- 300-ton welding rotators are often highly customized to meet the specific requirements of the application and the workpiece dimensions.

- Factors like the size of the turntable, the rotational speed, and the overall system configuration can be tailored to the project's needs.

- Improved Productivity and Efficiency:

- The precise positioning and controlled rotation capabilities of the 300-ton welding rotator can significantly enhance productivity and efficiency in the fabrication of large-scale industrial structures.

- It reduces the need for manual handling and positioning, allowing for more streamlined and consistent welding processes.

These 300-ton welding rotators are primarily utilized in heavy industries, such as shipbuilding, offshore oil and gas, power generation, and specialized metal fabrication, where the handling and welding of massive components are crucial.

✧ Main Specification

| Model | CR-300 Welding Roller |

| Load Capacity | 150 ton maximum*2 |

| Adjust Way | Bolt adjustment |

| Hydraulic adjust | Up/Down |

| Vessel Diameter | 1000~8000mm |

| Motor Power | 2*5.5kw |

| Traveling way | Manual traveling with lock |

| Roller wheels | PU |

| Roller size | Ø700*300mm |

| Voltage | 380V±10% 50Hz 3Phase |

| Control system | Wireless hand box |

| Color | Customized |

| Warranty | One year |

| Certification | CE |

✧ Feature

1.The pipe welding rollers product has following different series,say, the self-alignment, the adjustable, the vehicle, the tilting and the anti-drift types.

2.The series conventional pipe welding rollers stand is able to adopt to various diameter of job, by adjust the center distance of rollers, via reserved screw holes or lead screw.

3.Depends on different application, the roller surface has three types,PU/RUBBER/STEEL WHEEL.

4.The pipe welding rollers is mainly used for Pipe Welding ,tank rolls polishing,turning roller painting and tank turning rolls assembly of cylindrical roller shell.

5.The pipe welding turning roller machine can joint control with other equipments.

✧ Spare Parts Brand

1.Variable Frequency Drive is from Danfoss / Schneider brand.

2.Rotation and tilring Motors are Invertek / ABB brand.

3.Electric elements is Schneider brand.

All the spare parts are easily to replace at end user local market.

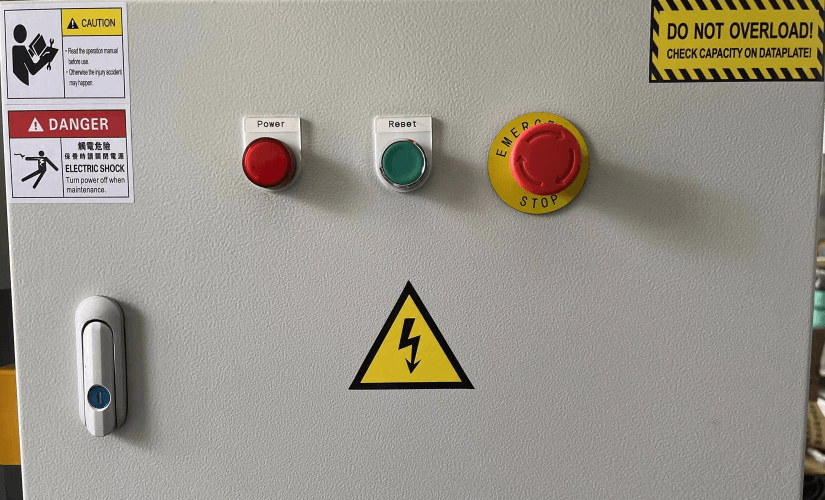

✧ Control System

1.Remote Hand control box with Rotation speed display, Rotation Forward , Rotation Reverse, Tilting Up, Tilting Down, Power Lights and Emergency Stop functions.

2. Main electric cabinet with power switch,Power Lights, Alarm , Reset functions and Emergency Stop functions.

3.Foot pedal to control the rotation direction.

4.We also add one additional Emergency stop button on the machine body side, this will ensure the work can stop the machine at the first time once any accident occur.

5.All our control system with CE approval to European market.

✧ Previous Projects