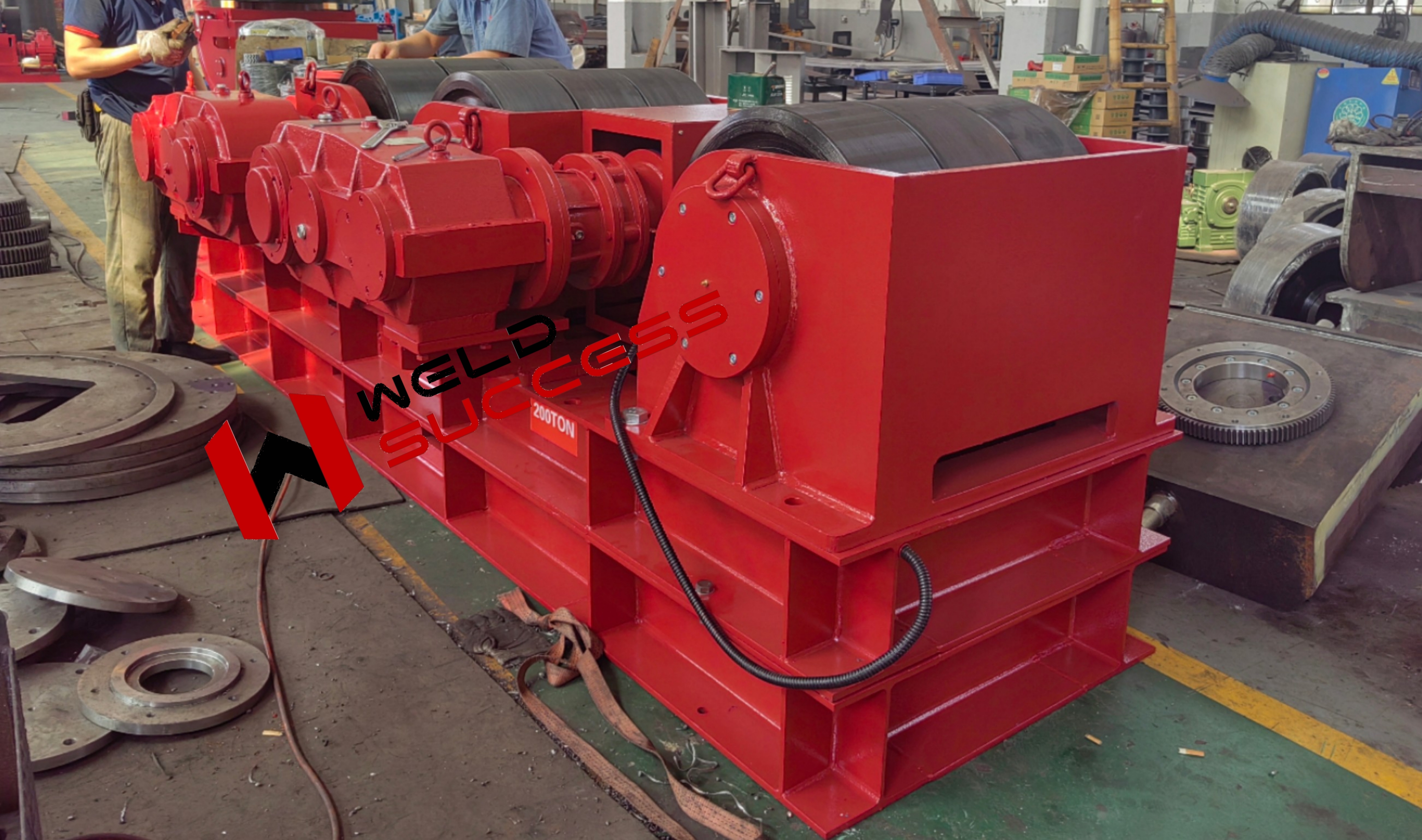

CR-40T Bolt adjustment Pipe Welding Rotator

✧ Introduction

1.One drive & one idler packaged together.

2.Remote hand control & foot pedal control.

3.Bolt adjustment for different diameter vessels.

4.Stepless adjustable speed of the driven part.

5.Drive rotation speed in digital readout.

6.Top-class electronic components from Schneider.

7.100% new from original manufacturer

✧ Main Specification

| Model | CR-40 Welding Roller |

| Turning Capacity | 40 Ton maximum |

| Loading Capacity-Drive | 20 Ton maximum |

| Loading Capacity-Idler | 20 Ton maximum |

| Vessel size | 500~4500mm |

| Adjust Way | Bolt adjustment |

| Motor Rotation Power | 2*1.5 KW |

| Rotation Speed | 100-1000mm/min |

| Speed control | Variable frequency driver |

| Roller wheels | Steel Material |

| Roller size |

Ø500*200mm

|

| Voltage | 380V±10% 50Hz 3Phase |

| Control system | Remote control 15m cable |

| Color | Customized |

| Warranty | One year |

| Certification | CE |

✧ Feature

1. Adjustable Roller position is very helpful in adjusting the rollers between the main body so that rollers of different diameter can be adjusted over the same rollers without even buying another size pipe roller.

2. A Stress analysis has been performed on the rigid body for the testing of the load capability of the frame on which the weight of the pipes depends on.

3.Polyurethane rollers are being used in this product because polyurethane rollers are weight resistant and can protect the surface of the pipes from being scratched up while rolling.

4. Pin mechanism is used to pin the polyurethane rollers on the main frame.

5. Adjustable stand is used to adjust the height of the Rigid Frame according to the need and requirement of welding the pipe and according to the comfort level of the welder so that it can provide maximum stability.

✧ Spare Parts Brand

1.Variable Frequency Drive is from Danfoss / Schneider brand.

2.Rotation and tilring Motors are Invertek / ABB brand.

3.Electric elements is Schneider brand.

All the spare parts are easily to replace at end user local market.

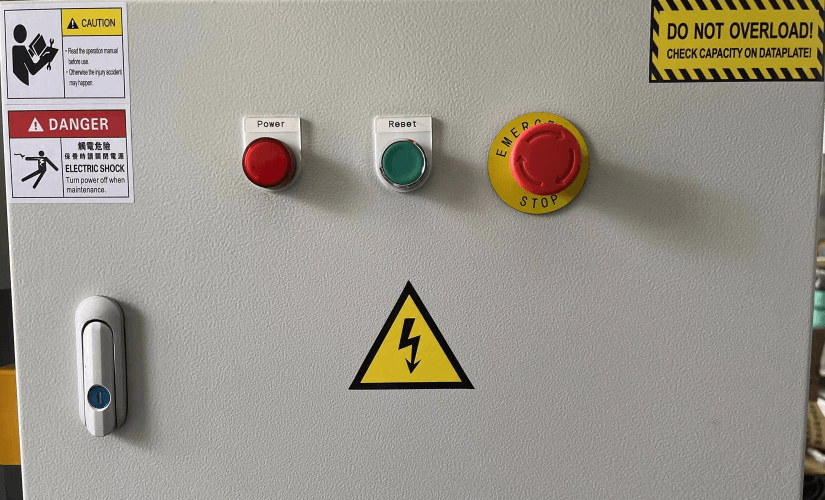

✧ Control System

1.Remote Hand control box with Rotation speed display, Rotation Forward , Rotation Reverse, Tilting Up, Tilting Down, Power Lights and Emergency Stop functions.

2. Main electric cabinet with power switch,Power Lights, Alarm , Reset functions and Emergency Stop functions.

3.Foot pedal to control the rotation direction.

4.We also add one additional Emergency stop button on the machine body side, this will ensure the work can stop the machine at the first time once any accident occur.

5.All our control system with CE approval to European market.

✧ Previous Projects