CR-60 Welding Rotators

✧ Introduction

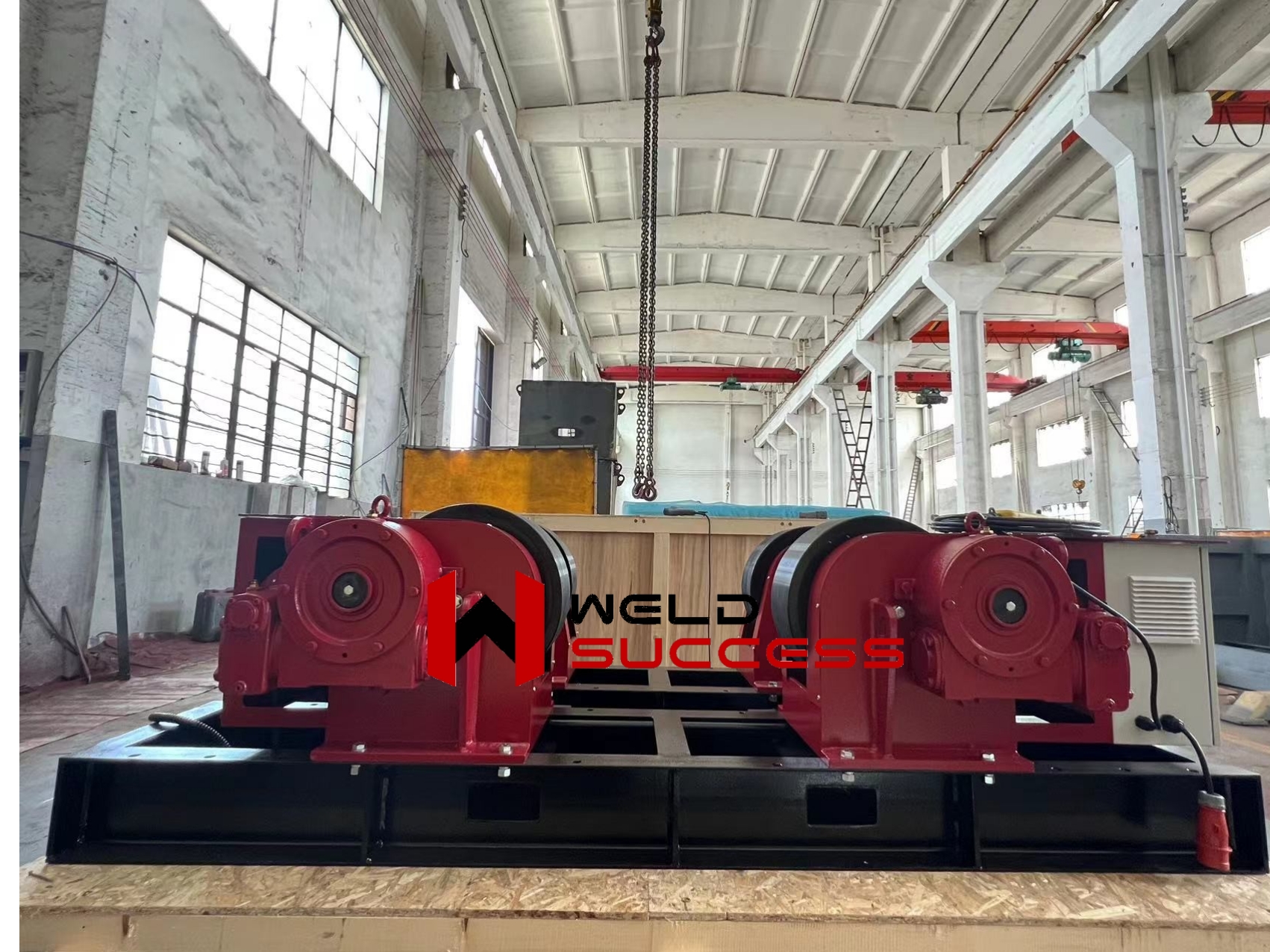

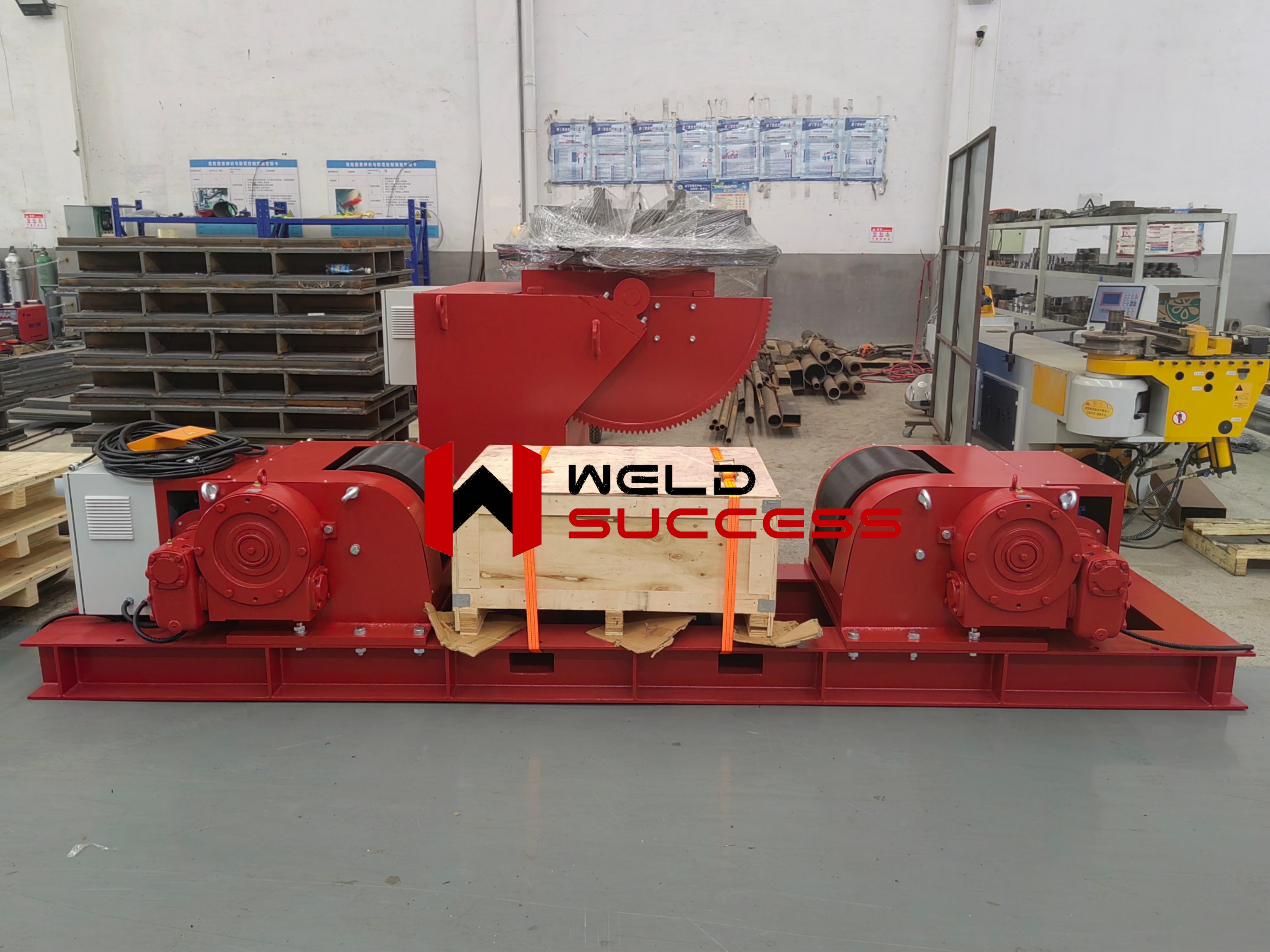

60-ton conventional welding rotator is a heavy-duty piece of equipment designed to support and rotate large cylindrical workpieces during the welding process. Here’s an overview of its features, specifications, and applications:

Key Features

- Load Capacity:

- Designed to handle up to 60 tons, making it suitable for heavy industrial applications.

- Rotating Rollers:

- Typically consists of two powered rollers that provide controlled rotation of the workpiece.

- Adjustable Roller Spacing:

- Allows for accommodating various pipe diameters and lengths.

- Speed Control:

- Equipped with variable speed control for precise adjustment of the rotation speed, enhancing welding quality.

- Robust Construction:

- Built with high-strength materials to withstand heavy loads and provide durability.

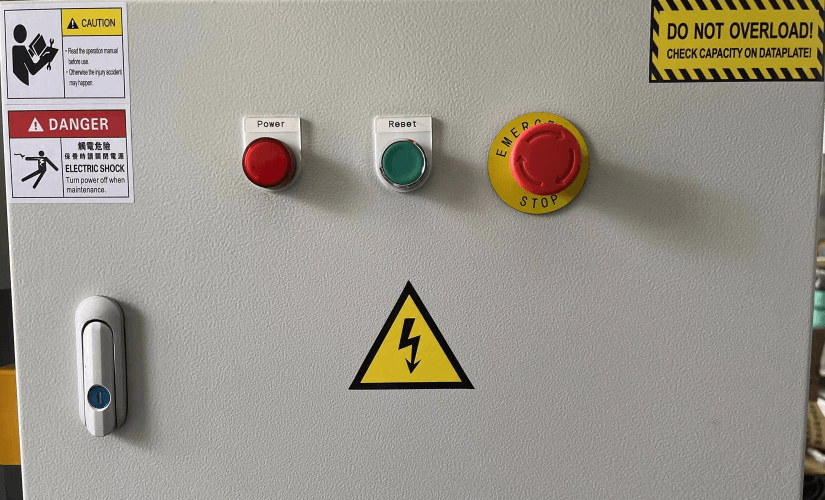

- Safety Features:

- Includes safety mechanisms such as overload protection, emergency stop buttons, and stable bases to prevent tipping.

Specifications

- Load Capacity: 60 tons

- Roller Diameter: Varies, often around 200-400 mm

- Rotation Speed: Typically adjustable, ranging from a few millimeters to several meters per minute

- Power Supply: Usually powered by electric motors; specifications may vary based on the manufacturer

Applications

- Pipeline Construction: Used in the oil and gas industry for welding large pipelines.

- Tank Fabrication: Ideal for constructing and welding large storage tanks and pressure vessels.

- Shipbuilding: Employed in the shipbuilding industry for welding hull sections and other large components.

- Heavy Machinery Manufacturing: Used in the fabrication of large machinery and equipment.

Benefits

- Enhanced Welding Quality: Consistent rotation aids in achieving uniform welds.

- Increased Efficiency: Reduces manual handling and speeds up the welding process.

- Versatility: Can be used with various welding techniques, including MIG, TIG, and submerged arc welding.

If you need more detailed information about specific models, manufacturers, or operational guidelines, feel free to ask!

✧ Main Specification

| Model | CR-60 Welding Roller |

| Turning Capacity | 60 Ton maximum |

| Loading Capacity-Drive | 30 Ton maximum |

| Loading Capacity-Idler | 30 Ton maximum |

| Vessel size | 300~5000mm |

| Adjust Way | Bolt adjustment |

| Motor Rotation Power | 2*2.2 KW |

| Rotation Speed | 100-1000mm/min |

| Speed control | Variable frequency driver |

| Roller wheels | Steel Material |

| Roller size |

Ø500*200mm

|

| Voltage | 380V±10% 50Hz 3Phase |

| Control system | Remote control 15m cable |

| Color | Customized |

| Warranty | One year |

| Certification | CE |

✧ Feature

1. Adjustable Roller position is very helpful in adjusting the rollers between the main body so that rollers of different diameter can be adjusted over the same rollers without even buying another size pipe roller.

2. A Stress analysis has been performed on the rigid body for the testing of the load capability of the frame on which the weight of the pipes depends on.

3.Polyurethane rollers are being used in this product because polyurethane rollers are weight resistant and can protect the surface of the pipes from being scratched up while rolling.

4. Pin mechanism is used to pin the polyurethane rollers on the main frame.

5. Adjustable stand is used to adjust the height of the Rigid Frame according to the need and requirement of welding the pipe and according to the comfort level of the welder so that it can provide maximum stability.

✧ Spare Parts Brand

1.Variable Frequency Drive is from Danfoss / Schneider brand.

2.Rotation and tilring Motors are Invertek / ABB brand.

3.Electric elements is Schneider brand.

All the spare parts are easily to replace at end user local market.

✧ Control System

1.Remote Hand control box with Rotation speed display, Rotation Forward , Rotation Reverse, Tilting Up, Tilting Down, Power Lights and Emergency Stop functions.

2. Main electric cabinet with power switch,Power Lights, Alarm , Reset functions and Emergency Stop functions.

3.Foot pedal to control the rotation direction.

4.We also add one additional Emergency stop button on the machine body side, this will ensure the work can stop the machine at the first time once any accident occur.

5.All our control system with CE approval to European market.