Spool Rotator

✧ Introduction

3-ton spool rotator is a specialized piece of equipment designed to facilitate the handling, positioning, and welding of cylindrical components such as spools, pipes, and other similar structures weighing up to 3 metric tons (3,000 kg). This type of rotator enhances efficiency and precision in various industrial applications, particularly in fabrication and assembly processes.

Key Features and Capabilities

- Load Capacity:

- Supports workpieces with a maximum weight of 3 metric tons (3,000 kg), making it suitable for medium-sized spools and cylindrical components.

- Rotational Mechanism:

- Equipped with a powerful motorized system that allows for smooth and controlled rotation of the spool.

- Variable speed control enables operators to adjust the rotation speed according to the specific welding or fabrication task.

- Adjustable Supports:

- Features adjustable cradles or supports that can accommodate different spool sizes and shapes, enhancing versatility.

- Designed to securely hold the spool in place during operation.

- Tilt Functionality:

- Many models include a tilting mechanism, allowing operators to adjust the angle of the spool for better accessibility during welding or inspection.

- This functionality improves ergonomics and reduces operator strain.

- Integrated Safety Features:

- Safety mechanisms such as emergency stop buttons, overload protection, and secure locking systems are included to ensure safe operation.

- Designed to maintain a secure working environment for operators.

- Seamless Integration with Welding Equipment:

- Compatible with various welding machines, including MIG, TIG, and submerged arc welders, facilitating a smooth workflow during operations.

- Versatile Applications:

- Commonly used in industries such as:

- Oil and gas for pipeline construction

- Shipbuilding for handling cylindrical hull sections

- Heavy machinery manufacturing

- General metal fabrication

- Commonly used in industries such as:

Benefits

- Enhanced Productivity: The ability to easily rotate and position spools reduces manual handling and improves overall workflow efficiency.

- Improved Weld Quality: Controlled rotation and positioning contribute to high-quality welds and better joint integrity.

- Reduced Labor Costs: Automating the rotation process minimizes the need for additional labor, lowering overall production costs.

3-ton spool rotator is an essential tool for industries that require precise handling and welding of cylindrical components, ensuring safety, efficiency, and high-quality results in fabrication operations. If you have any specific questions or need further information about 3-ton spool rotators, feel free to ask!

✧ Main Specification

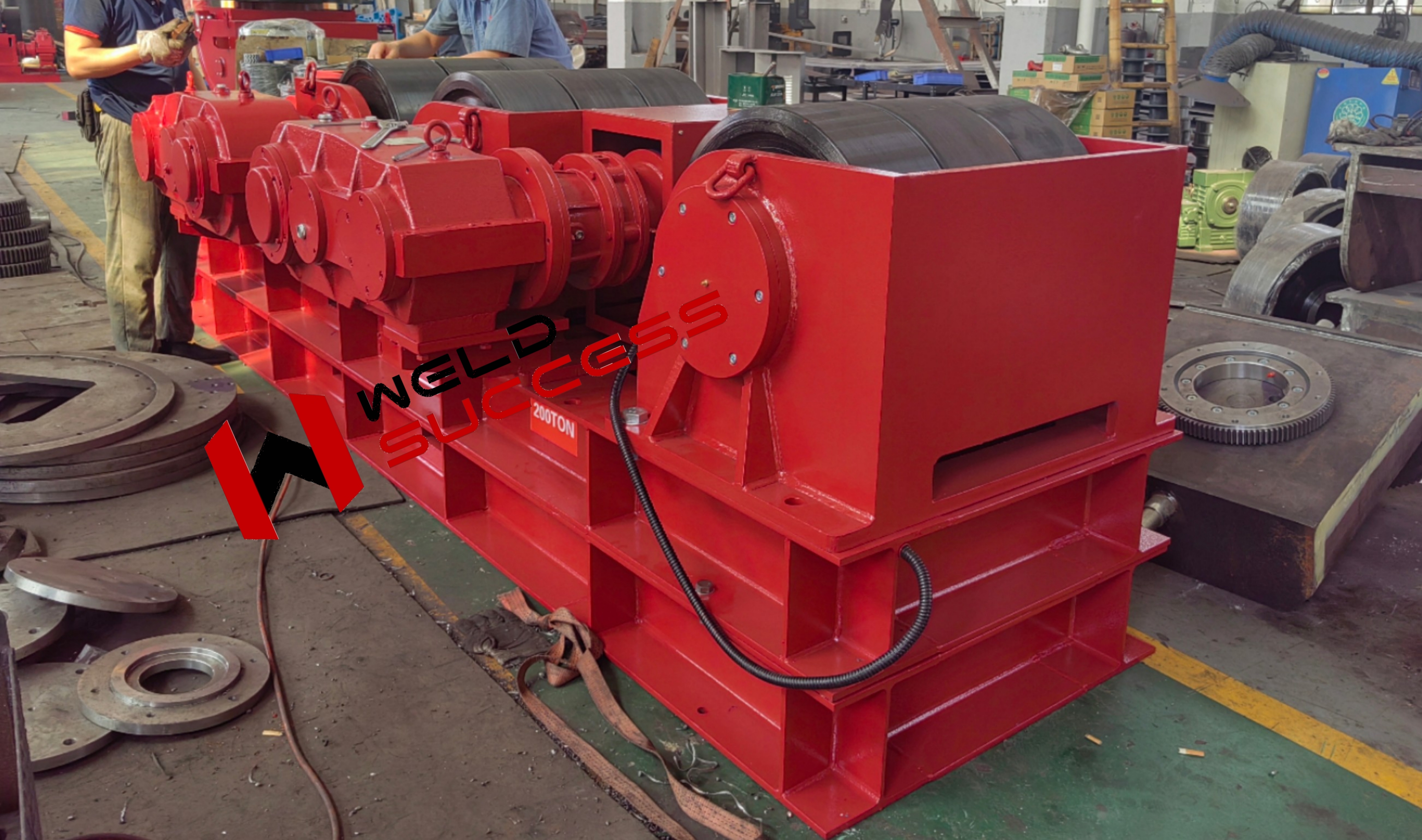

| Model | PT3 Spool Rotator |

| Turning Capacity | 3 tons maximum |

| Rotator Speed | 100-1000mm/min |

| Pipe diameter range | 100~920mm |

| Pipe diameter range | 100~920mm |

| Motor Rotation Power | 500W |

| Wheel materials | RUBBER |

| Speed control | Variable frequency driver |

| Roller wheels | Steel coated with PU type |

| Control system | Remote hand control box & Foot pedal switch |

| Color | RAL3003 RED & 9005 BLACK / Customized |

| Options | Large diameter capacity |

| Motorized traveling wheels basis | |

| Wireless hand control box |

✧ Spare Parts Brand

For international business, Weldsuccess use all the famous spare parts brand to ensure the welding rotators with long time using life. Even the spare parts broken after years later, the end user also can replace the spare parts easily at the local market.

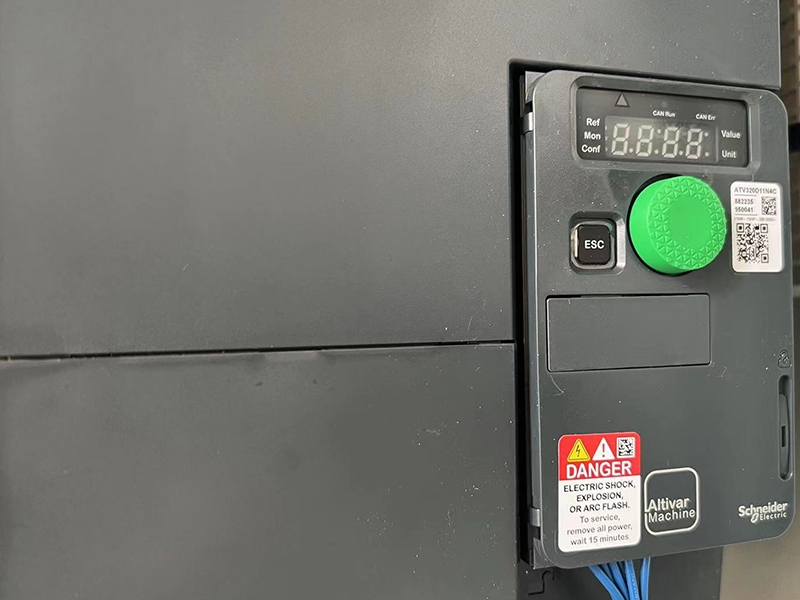

1.Frequency changer is from Damfoss brand.

2.Motor is from Invertek or ABB brand.

3.Electric elements is Schneider brand.

✧ Control System

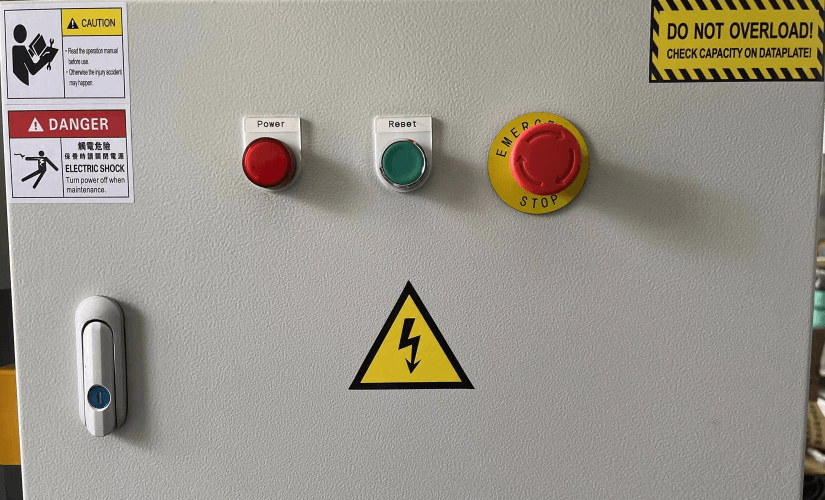

1.Hand control box with Rotation speed display, Forward , Reverse, Power Lights and Emergency Stop functions.

2.Main electric cabinet with power switch,Power Lights, Alarm , Reset functions and Emergency Stop functions.

3.Foot pedal to control the rotation direction.

4.Wireless hand control box is available if needed.

✧ Why Choose Us

Weldsuccess operate out of company-owned manufacturing facilities 25,000 sq ft of manufacturing & office space.

We export to 45 countries around the world and proud to have a large and growing list of customers, partners and distributors on 6 continents.

Our state of the art facility utilizes robotics and full CNC machining centers to maximize productivity, which is returned in value to customer through lower production costs.

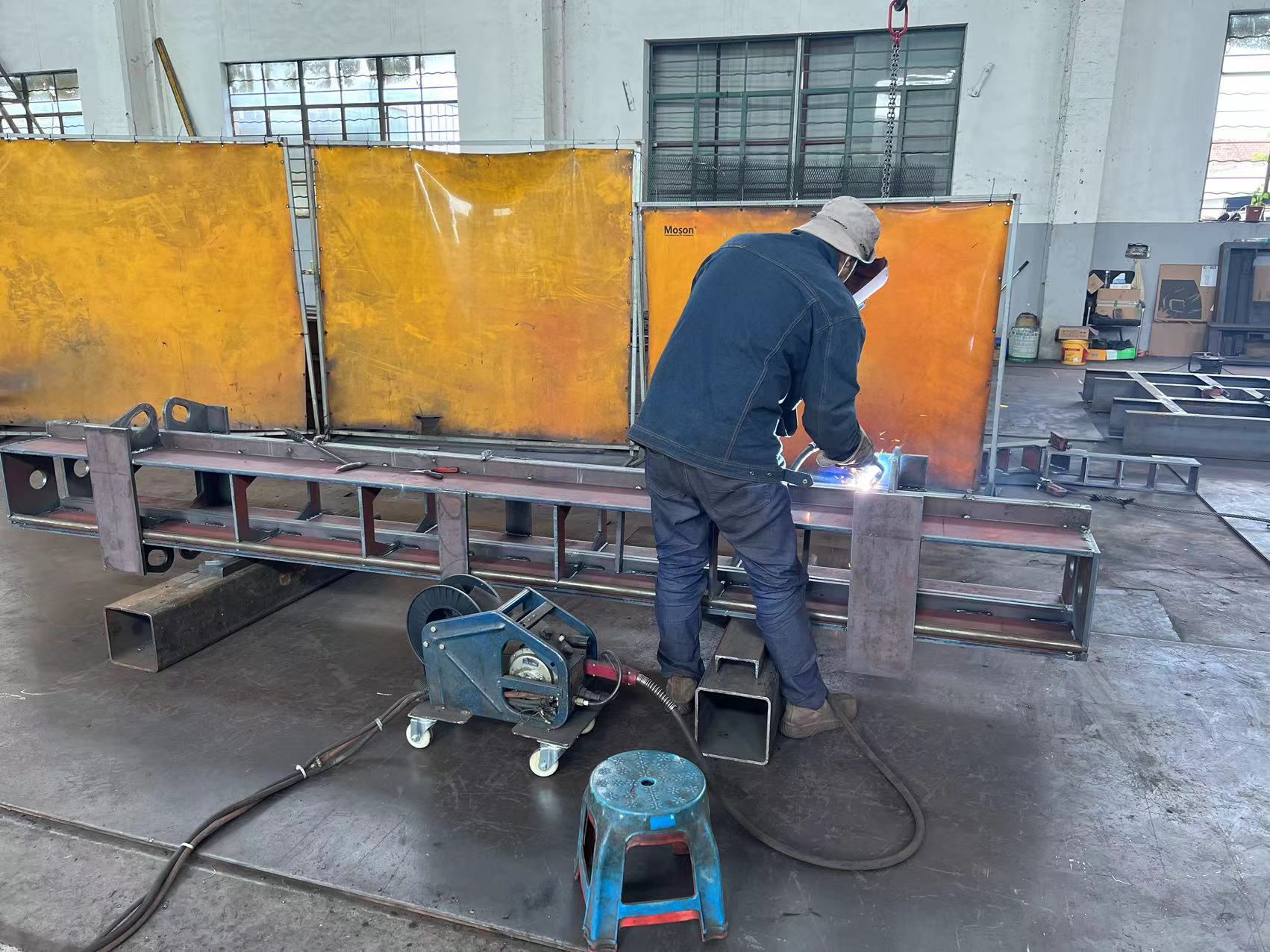

✧ Production Progress

Since 2006, we passed the ISO 9001:2015 quality management system, we control the quality from the original material steel plates. When our sales team proceed the order to production team, at the same time will reqeust the quality inspection from the original steel plate to final products progress. This will ensure our products meet the customers requirment.

At the same time, all of our products got the CE approval from 2012, so we can export to Europeam market freely.

✧ Previous Projects